Trends in cathodic protection: 5 innovations to know about

Cathodic protection is a critical component in the prevention of corrosion in industrial infrastructure. With the constant advancement of technology and best practices, it is essential for engineers, managers and consultants to stay current on the latest trends in this field. In this article, we will explore five current trends in cathodic protection that are critical for any manager looking to optimize their systems and ensure the longevity of their assets.

This is what you need to know to stay ahead of the curve and provide maximum optimization for your projects:

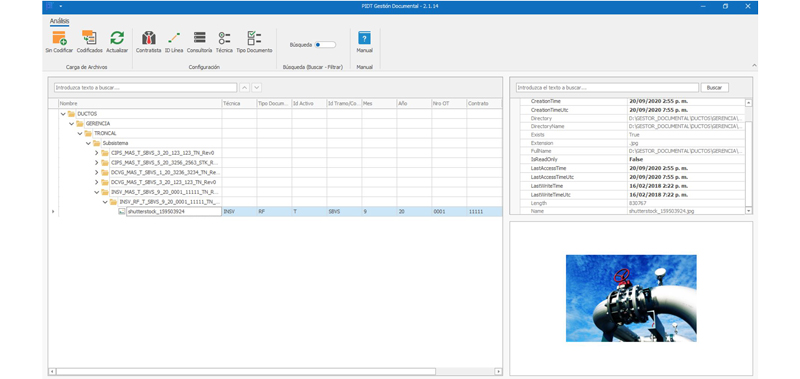

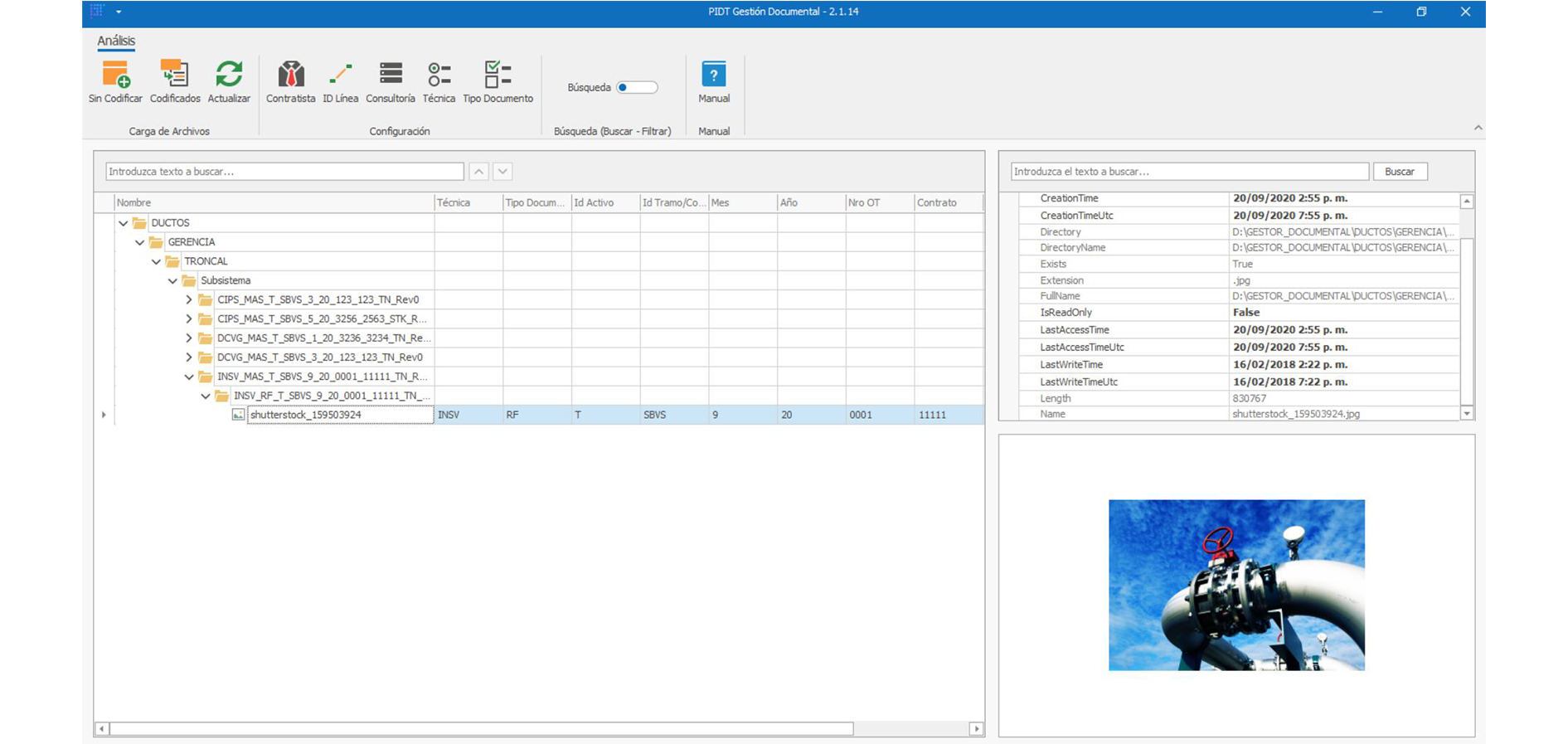

- Remote Monitoring and IoT Technology

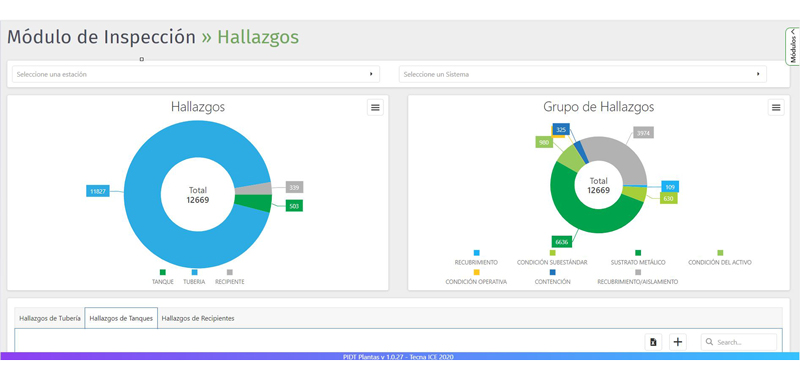

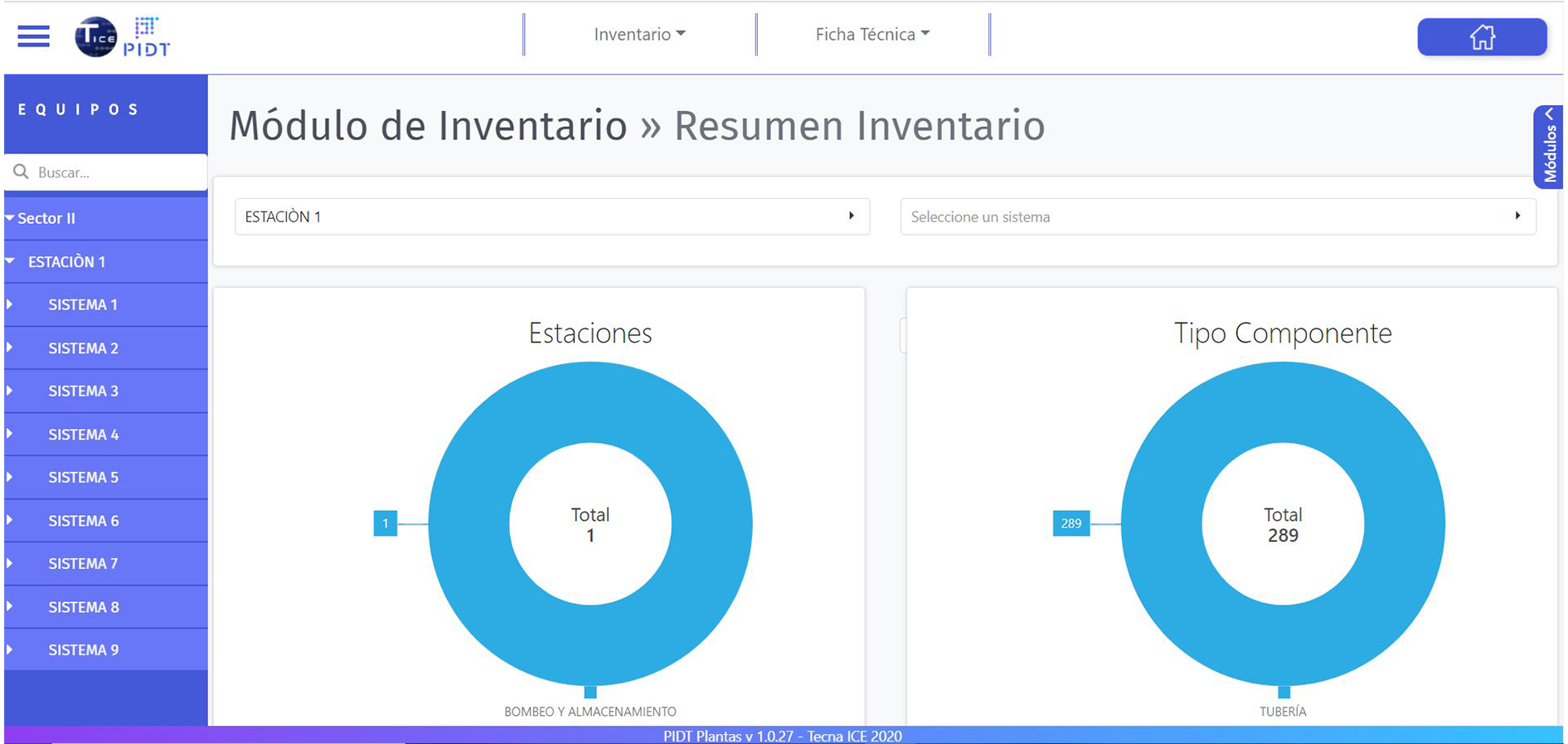

Digitization has transformed the way cathodic protection systems are designed, implemented and monitored. Smart sensors, SCADA systems and real-time data analysis enable more accurate and efficient monitoring of the condition of structures. In addition, the use of drones and underwater robots facilitates inspections in hard-to-reach areas, improving safety and reducing costs by allowing problems to be detected before they become costly failures. This trend not only improves operational efficiency, but also reduces the time and costs associated with physical inspections.

- Self-repairing coatings

Advances in materials have led to the development of self-healing coatings, which can repair minor damage automatically. This means that protected structures can maintain their integrity without the need for frequent interventions, resulting in a significant reduction in long-term maintenance costs. This type of technology not only improves durability, but also optimizes overall system performance.

- High Energy Anodes

Anodes are the heart of cathodic protection systems. Researchers are developing new materials with improved efficiency, durability and adaptability to different environments. Sacrificial anodes based on magnesium and aluminum alloys, as well as dimensional anodes with special coatings, are some of the most promising options.

High-energy anodes are gaining popularity due to their ability to generate higher currents and provide more efficient protection. These anodes have an extended service life, which reduces the frequency of replacement and maintenance. Their implementation can be crucial for projects where efficiency and cost reduction are priorities.

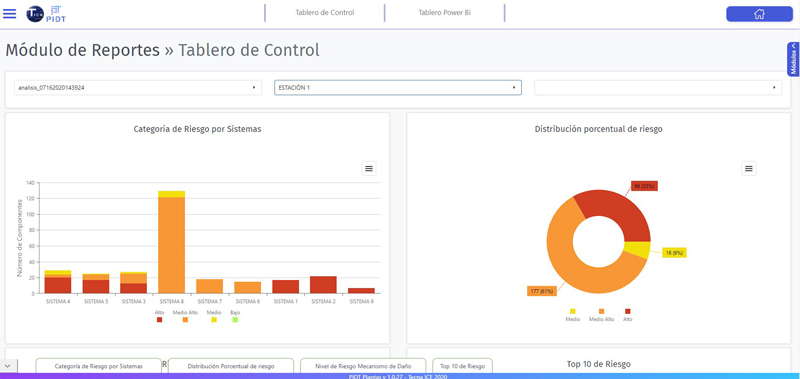

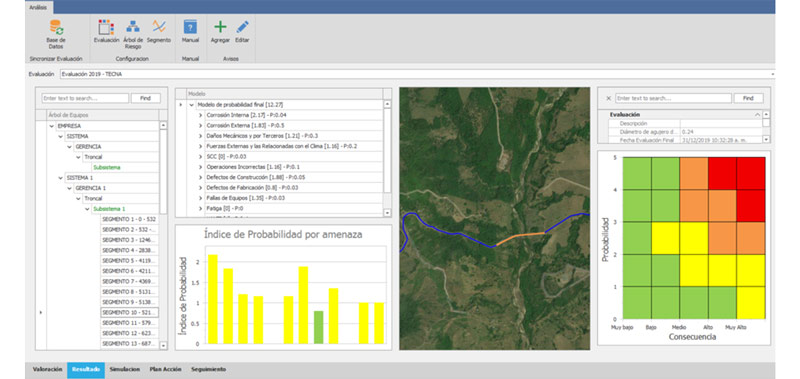

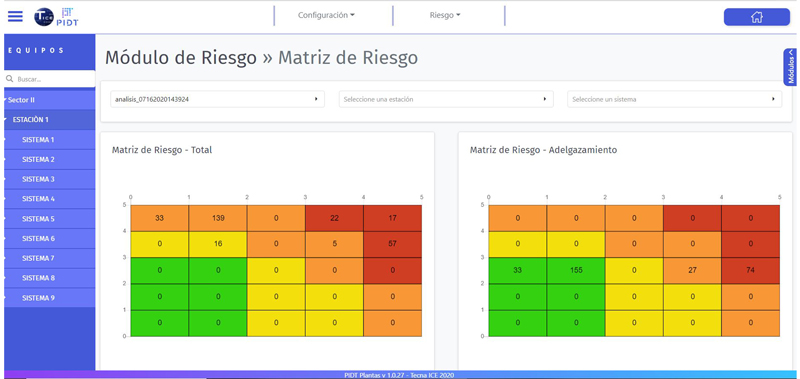

- Advanced Simulation and Modeling

The use of advanced modeling and simulations allows engineers to better understand corrosion mechanisms and optimize cathodic protection system design. These tools enable predictive analyses that can guide decisions about materials and methods, ensuring more effective implementation. The ability to model different scenarios helps anticipate problems before they occur.

- Sustainable and eco-efficient solutions

Sustainability is a priority for many companies. Among the most representative innovations is the use of renewable energy in protection systems such as solar and wind energy because they offer an attractive alternative to traditional sources, especially in remote locations or with limited access to the electrical grid, in addition to the recycling of components and low energy consumption design.

Trends in cathodic protection are evolving rapidly, driven by technological innovations, sustainability and the quest for greater operational efficiency. For project managers, keeping up to date is crucial to ensure the integrity and durability of the steel structures under their responsibility. Adopt innovative solutions, such as the TECNA current interrupter allows not only to comply with current regulations, but also to optimize resources and improve the development of inspections and thus maintain the good performance of cathodic protection systems in the long term.

References:

- American Petroleum Institute (API)

- International Organization for Standardization (ISO)

- Scientific papers published in specialized journals such as Corrosion Science and Journal of the Electrochemical Society

- https://www.dreiym.com/es/2024/06/11/replantearse-la-proteccion-del-diseno-catodico-tendencias-actuales-y-mejores-practicas/

- https://inspenet.com/articulo/tecnologias-en-la-proteccion-catodica/

- https://inspenet.com/articulo/anodos-de-zinc-en-la-proteccion-catodica/

- https://www.dreiym.com/es_pr/2024/04/02/tres-retos-comunes-del-diseno-integral-de-la-proteccion-catodica/

- https://tecna-ice.com/la-proteccion-catodica-explicada/