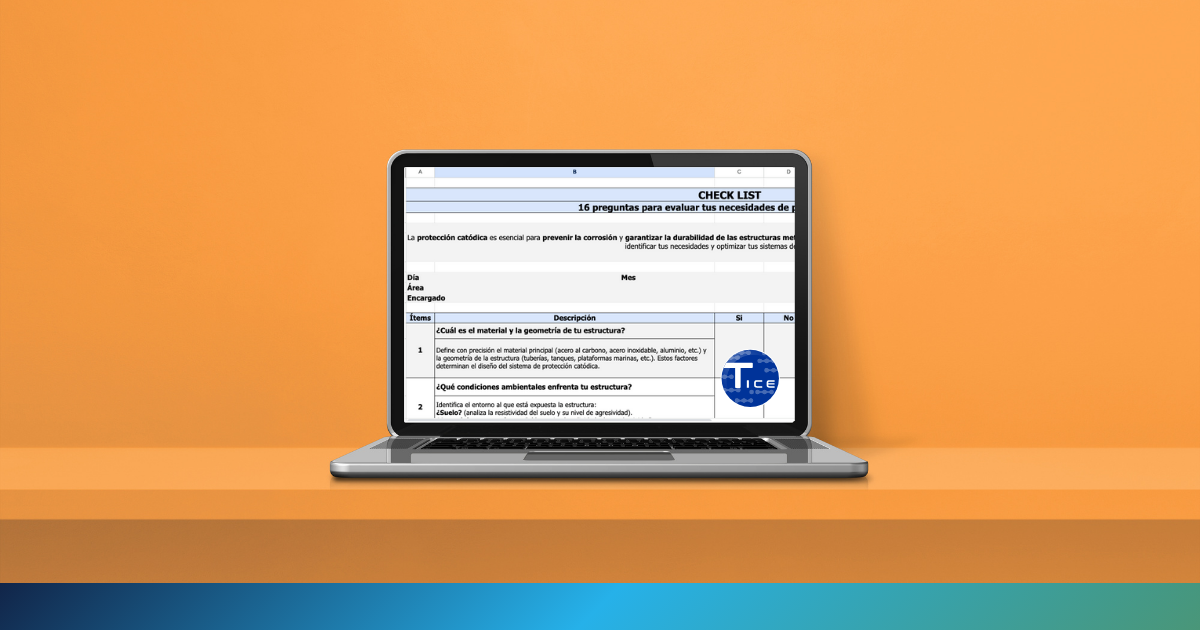

Cathodic Protection Checklist: Identify Your CP Needs

Cathodic protection is essential to prevent corrosion in pipelines, tanks, and metallic structures, but its effectiveness depends on continuous evaluation. Without proper diagnosis, risks such as premature failure, accelerated corrosion, or electrical interference can threaten your asset integrity.

Why use a Cathodic Protection Checklist?

A Cathodic Protection Checklist is a simple yet powerful tool for integrity engineers and CP specialists. It helps ensure no critical aspect is overlooked, guiding the evaluation of operational and environmental factors that impact system performance.

By systematically reviewing your CP system with targeted questions, you can detect potential deficiencies early and prevent costly failures.

What does the Technical Checklist include?

Our Technical Checklist is structured to help you assess key areas, such as:

- Is the material of the structure suitable for the cathodic protection system implemented?

- Have environmental conditions that could affect corrosion been identified?

- Have recent inspections been performed on the protective coating?

- Is there a historical record of corrosion failures in the infrastructure?

- Have external current interferences been identified that may affect the efficiency of the system?

The checklist contains:

📌 16 key questions to evaluate the current state of your cathodic protection system.

📌 A section for observations to document findings and potential improvements.

This checklist is not a substitute for a technical audit, but it is a valuable resource for engineers seeking a fast and structured diagnosis of their CP system.

If any answers reveal uncertainty or gaps, our experts at Tecna ICE are ready to support you with advanced cathodic protection services, audits, and technical consulting.

Answering these questions will allow you to detect possible deficiencies and plan your strategy. Contact us when you see that the answer to these questions requires support from our services in Cathodic Protection.

Download the Checklist Now

To access the Cathodic Protection Technical Checklist, simply complete the form below. Your information will be used only to provide high-value technical content about cathodic protection and asset integrity management.

Did you find this content useful?

Subscribe to receive technical articles, updates, and more directly in your inbox.

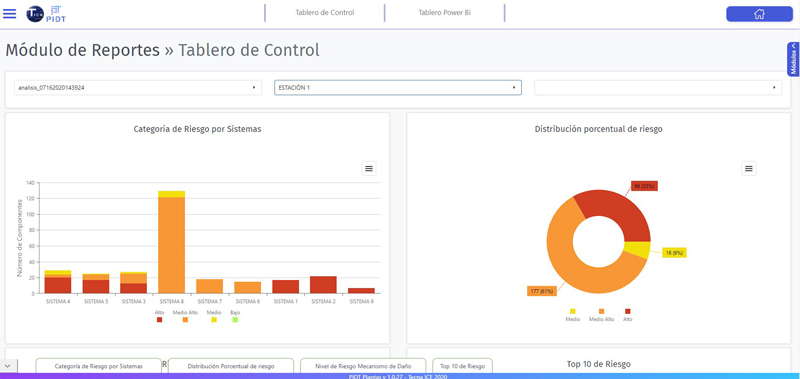

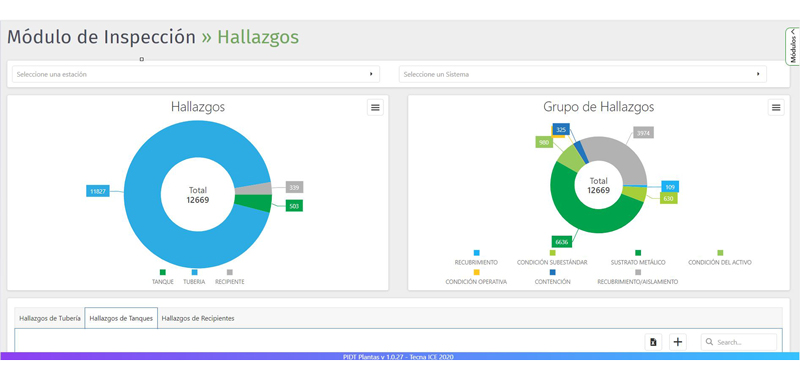

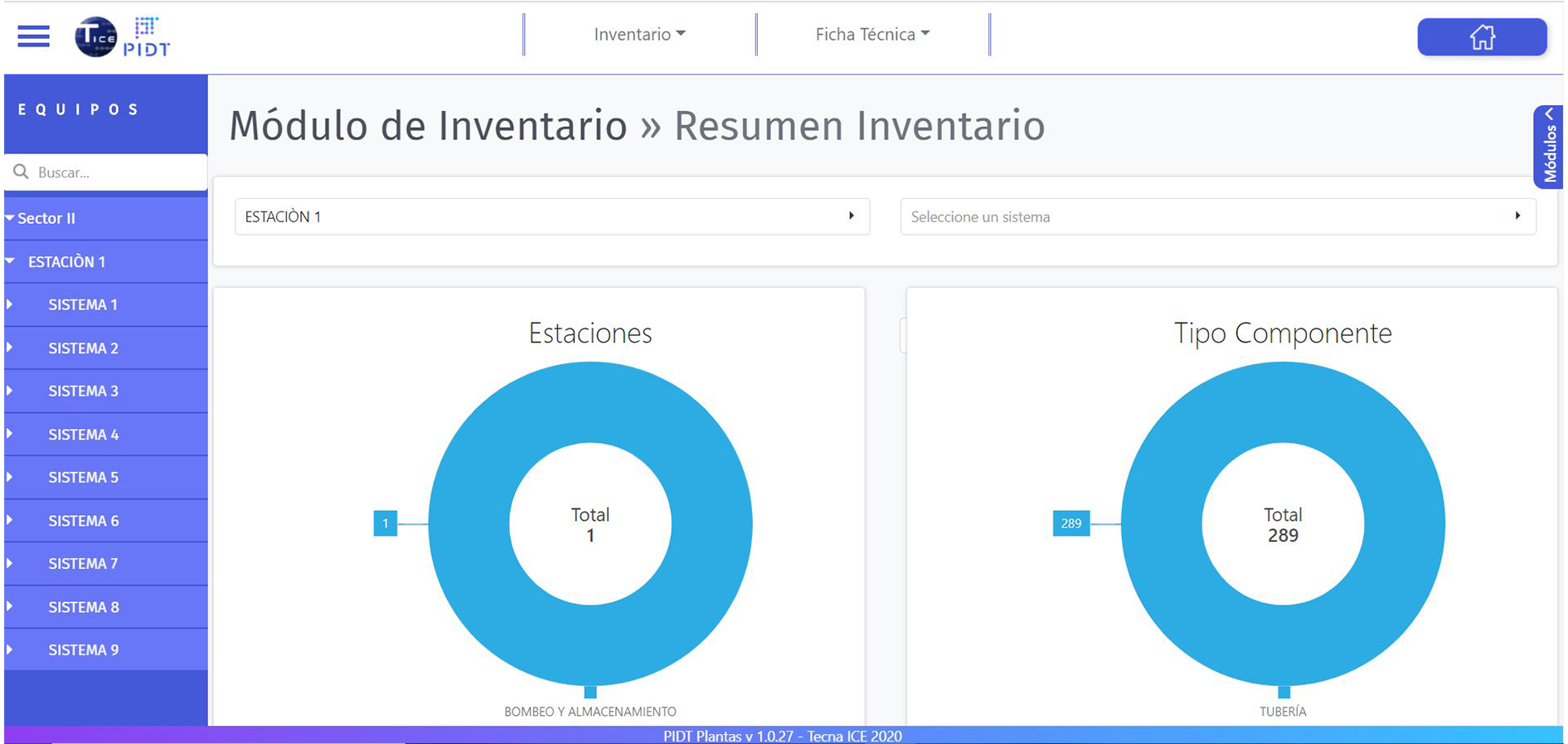

Looking for a solution like this?

Explore our specialized services in asset integrity engineering and applied technology.