Benefits of Using Advanced Current Interrupters in CP Inspection

Advanced current interrupter technology is transforming the way cathodic protection (CP) inspections are performed on pipelines, storage tanks, and other critical assets. The use of an advanced current interrupter not only improves inspection accuracy, but also enhances system reliability and ensures compliance with international standards.

What is a Current Interrupter for CP Inspections?

A current interrupter is an electronic device used during cathodic protection inspections to accurately control and measure electric current. Unlike conventional circuit breakers, an advanced current interrupter offers features such as:

-

Precision control: Adjust current to the system’s optimal level.

-

Greater durability: Engineered to withstand harsh environments.

-

Brand synchronization: Use GPS or time signals to synchronize multiple interrupters—even across different brands—for simultaneous “on/off” measurements.

Key Benefits of Using Advanced Current Interrupters

According to the AMPP report (2022), corrosion generates global costs of $2.5 trillion per year, representing 3.4% of the world’s GDP. Performing inspections with modern cathodic protection equipment, such as state-of-the-art current interrupters, can reduce these costs by up to 15%.

Unlike conventional circuit breakers, the new circuit breakers for cathodic protection system inspection incorporate state-of-the-art technologies that allow:

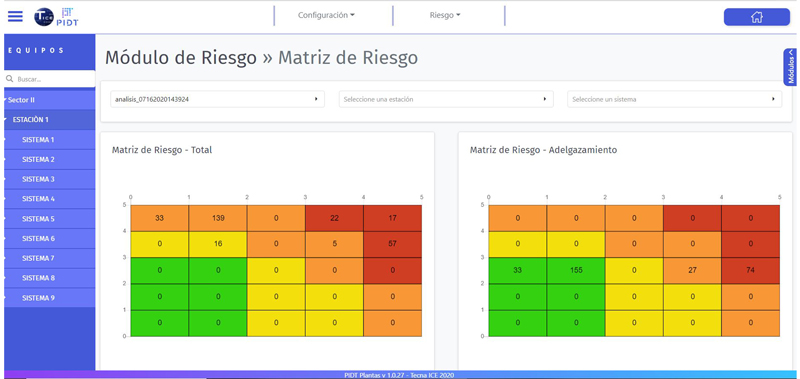

1. Reduced Operating Costs:

AMPP reports corrosion costs at $2.5 trillion yearly (3.4% of global GDP). Using advanced interrupters in inspections can reduce these costs by up to 15%.

2. Improved System Reliability:

Manufactured with high-quality, durable materials, advanced interrupters ensure consistent performance—even in marine or high-salinity environments.

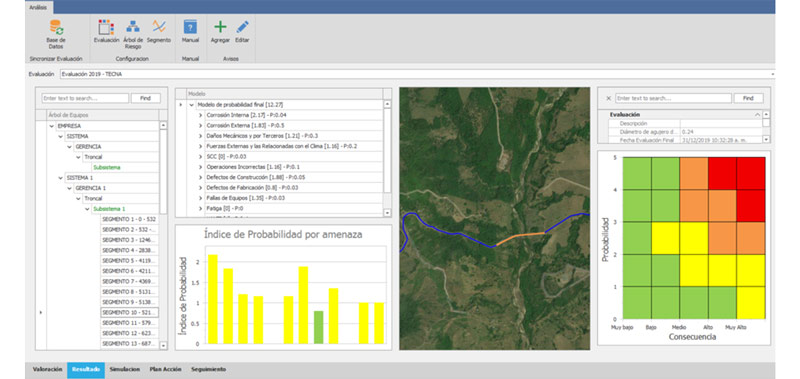

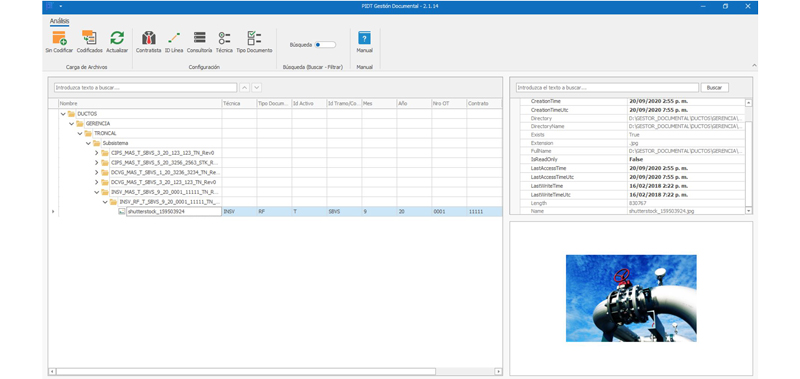

3. Real-Time Monitoring & Accuracy:

Integrated sensors provide live data on current, voltage, and environmental conditions. According to ACICOR, proactive monitoring systems can prevent up to 70% of failures.

4. Flexibility for Any Project:

Advanced interrupters are adaptable for large pipelines or small-scale assets, making them a flexible, scalable investment.

5. Multi-Brand Synchronization:

Seamless integration with equipment from different manufacturers—critical for mixed-system inspections.

6. Sustainability:

Optimized energy use lowers the operation’s carbon footprint and reduces the need for frequent replacements, extending asset life.

7. Regulatory Compliance:

Helps meet ISO 15589-1 and API RP 651 standards—crucial for safety, audits, and industry requirements.

The CP current interrupters not only represent a technological breakthrough in the evaluation of cathodic protection systems, but also offer a comprehensive solution to optimize costs, improve reliability and adapt to modern market requirements.

Why Choose the TECNA Current Interrupter?

The TECNA Current Interrupter combines state-of-the-art technology with a robust, reliable design:

-

Modular Control: Separate programming and power modules.

-

Resilient GPS Cycle: Long-range antenna and autonomous backup for GPS loss.

-

Intuitive Interface: Color display, hot keys, easy configuration.

-

Brand Compatibility: Sync with multiple brands, ON/OFF start options.

-

Durability: IP67-rated housing, rugged connectors, efficient heat dissipation.

-

Dual Power: Operates on AC/DC for flexible deployment.

With the TECNA Interrupter, you can improve your CP system inspections, achieve greater operational efficiency, extend asset lifespan, and ensure compliance with demanding industry standards.

“Advanced interrupters: accuracy, efficiency, and reliability in every inspection.”

Interested in the TECNA Current Interrupter? Learn more

References:

- AMPP International (2022). Cost of Corrosion Study. Retrieved from ampp.org.

- AMPP. (2023). Materials Protection and Performance Report.

- Energy and Technology Magazine. (2023). “Trends in cathodic protection for critical infrastructure.”

- AMPP International. (2023). “Corrosion Control Standards.

- – API RP 651. “Cathodic Protection of Aboveground Storage Tanks”.

- – ISO 15589-1. “Petroleum and natural gas industries – Cathodic protection of pipeline transportation systems”.

- https://tecna-ice.com/la-proteccion-catodica-explicada/