Technology in risk management: impact and application

Technology applied to operational risk is redefining how industrial organizations manage integrity, security and business continuity. In an environment where every decision can have critical consequences, new digital developments make it possible to anticipate, prioritize and act with an unprecedented level of precision.

Advanced models to understand risk

Advanced models allow a deeper and more accurate analysis of risks, based on historical data and predictive analytics. This not only improves the accuracy of risk identification, but also optimizes resources by prioritizing corrective actions.

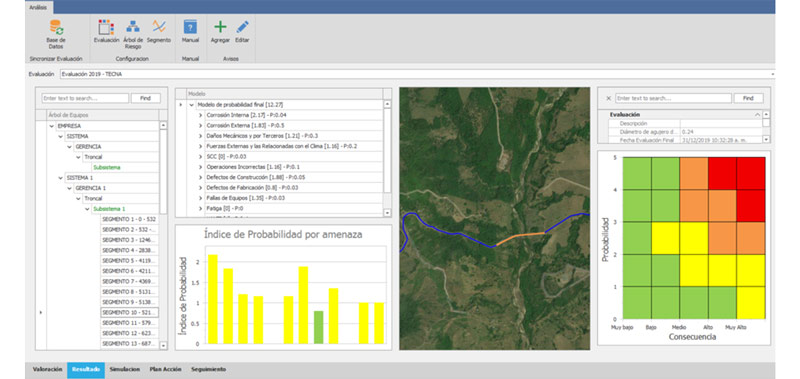

Today, the use of probabilistic models, BOWTIE trees and 3D simulations allows the technical teams of companies such as those in the oil & gas sector to identify emerging threats, calculate the potential impact of each scenario and draw mitigation paths.

“Companies that adopt technology in their integrity management system have been able to reduce incidents related to mechanical failures by up to 30%” (International Journal of Risk and Safety in Medicine, link).

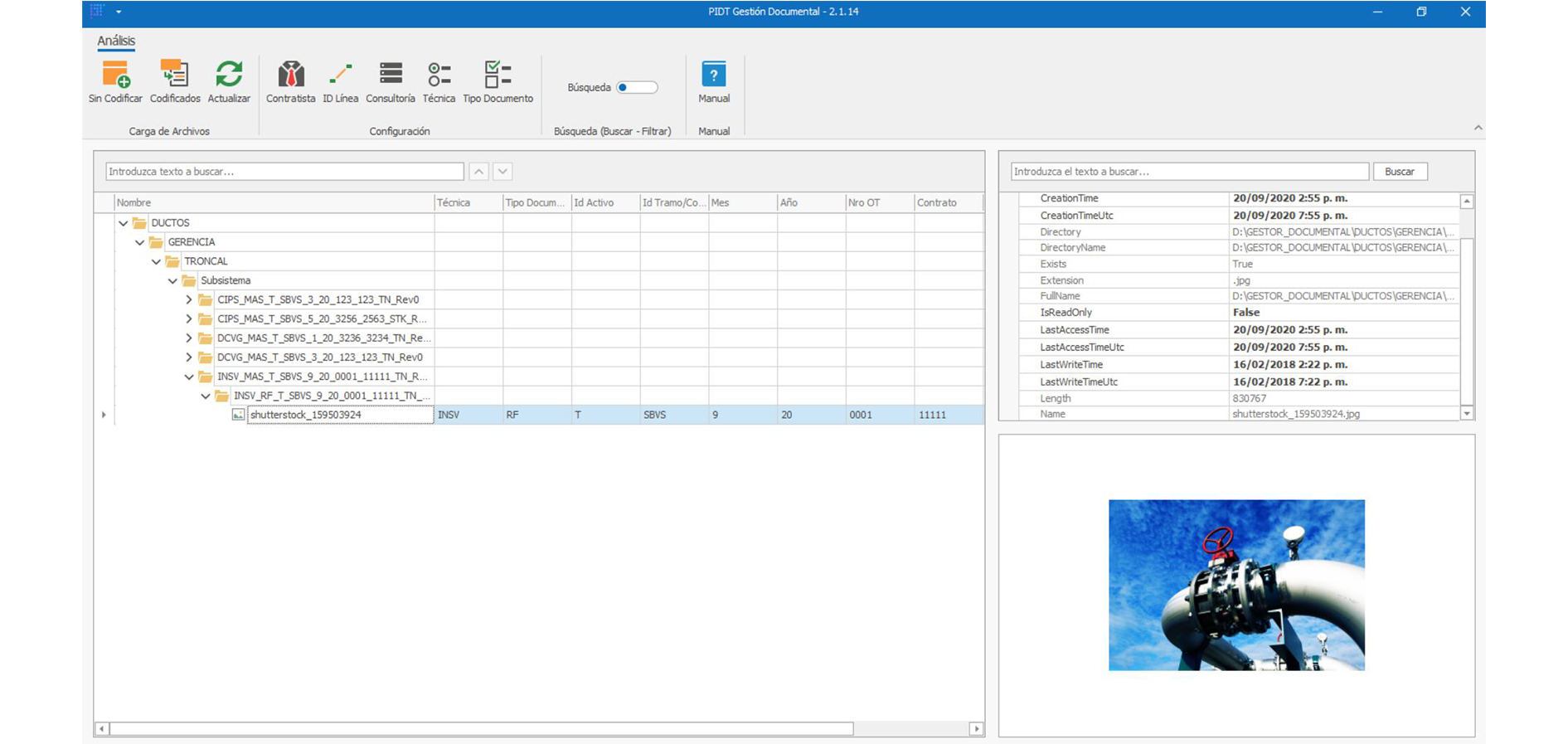

Data integration for informed decisions

The integration of relevant technical data enables risk managers to make informed, fact-based decisions. This data-driven approach translates into safer and more efficient operations, keeping regulatory compliance up to date and ensuring operational continuity.

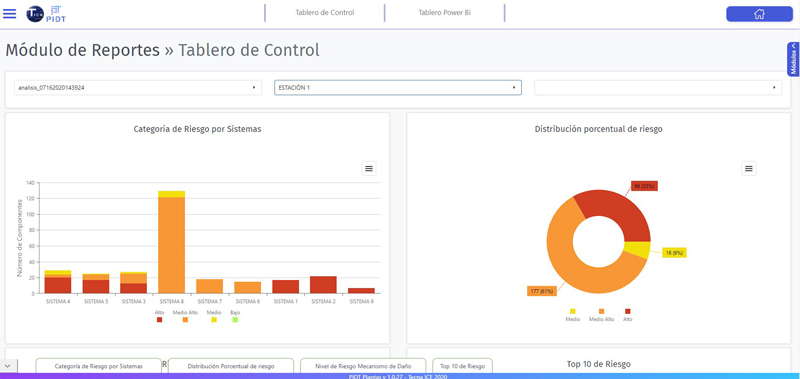

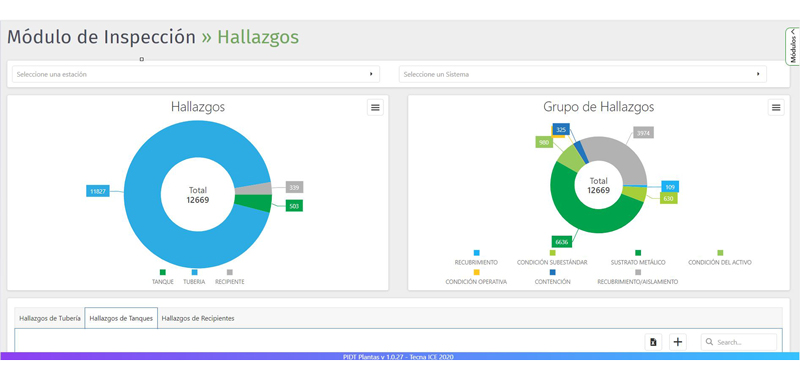

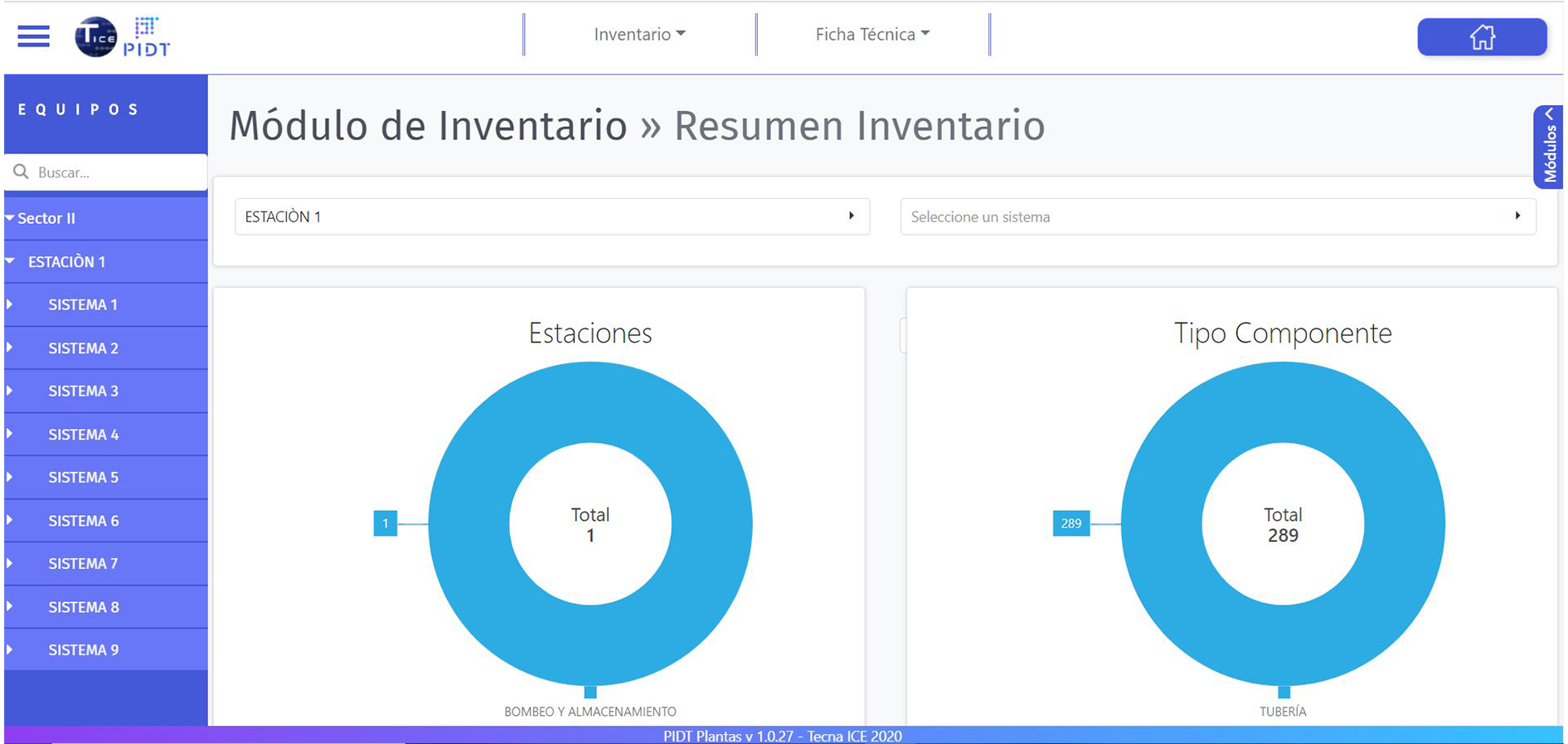

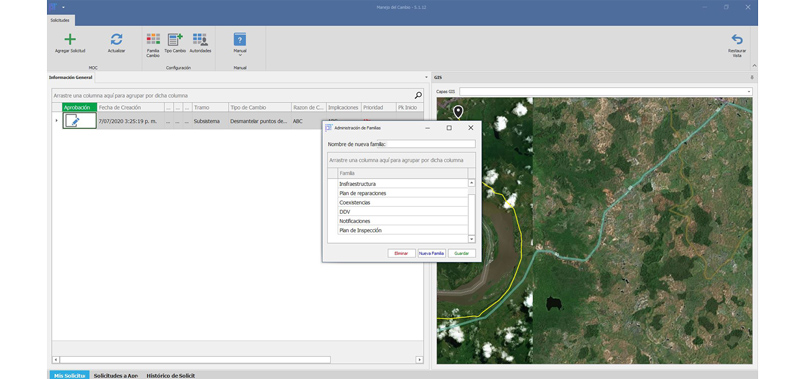

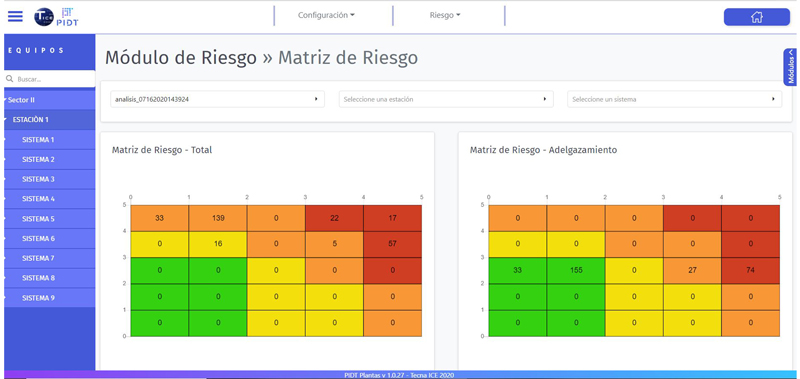

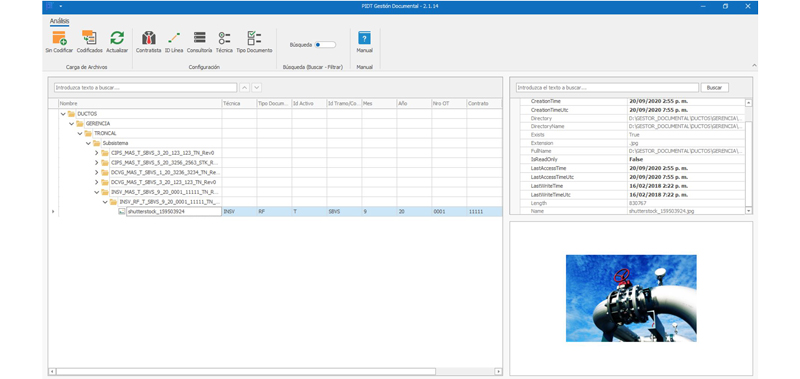

Instead of working with spreadsheets and isolated reports, solutions such as TECNA ICE’ s PIDT ecosystem integrate information from inspections, defect analysis, geotechnical assessments and risk maps into a single visual environment. This allows full traceability of decisions and better resource allocation.

Early warnings and geopositioning

Geo-referenced early warnings serve as a shield against potential incidents, providing near real-time alerts on conditions that could jeopardize infrastructure. This technology gives engineers the ability to react proactively, thus minimizing the impact of risks well before they occur.

With tools such as consequence viewers and emergency dashboards, geo-referenced alerts allow rapid action to be taken in the event of events such as landslides, structural failures or leaks. This technology has been key in projects in Colombia, where interventions near HCAs (High Consequence Areas) have been prioritized.

Frictionless regulatory compliance

Modern digital solutions not only facilitate risk management, but also ensure easier regulatory compliance. Advancing compliance with standards such as ISO 55000 and other industry-specific regulations becomes more effective with the use of technology.

Compliance modules within PIDT ensure that mitigation plans are aligned with standards such as API 580/581, ASME B31.8s and Decree 2157. Automatic reports can be generated for auditors or regulatory bodies, avoiding improvisation.

Real-time intelligence to reduce costs

The applied technology not only improves safety, but also reduces operational costs. A McKinsey study reveals that the use of digital twins in industrial infrastructure can reduce maintenance costs between 20% and 25%(McKinsey & Co.).

In conclusion…

Technology does not replace technical expertise, but it enhances its impact. As regulatory and operational pressures grow, companies that invest in digital solutions have a tangible competitive advantage: more security, fewer incidents and data-backed decisions.

At TECNA ICE, we accompany our clients in the adoption of technology for operational risk management, with solutions such as PIDT Pipelines and Plants, risk viewers and regulatory compliance tools.

Did you find this content useful?

Subscribe and receive technical articles, updates and more in your inbox.

Looking for a solution like this?

Let’s talk about how to transform risk management in your organization!