// PIDT Software

Industrial Plant Integrity Management Software

For technical decisions with regulatory support.

Based on API 580/581 and RBI analysis

For technical decisions with regulatory support.

Based on API 580/581 and RBI analysis

Many industrial plants face critical challenges in maintaining operational integrity. Manual management and lack of integration hinder regulatory compliance and increase the risk of static equipment failures.

Without a specialized digital solution, decisions are made with incomplete or outdated information, impacting productivity and safety.

PIDT Plants Software is a comprehensive solution designed to transform how you manage your static equipment. It integrates, analyzes and projects risk data under API RP 580/581 standards, facilitating decision making with technical accuracy and operational efficiency.

Outstanding functionalities:

Digitizes inspections and reports to reduce management time and technical analysis.

Avoid unexpected outages thanks to mitigation plans based on actual risk.

Make decisions based on reliable data, API standards and structured analysis.

Avoid penalties by integrating standards such as API 580/581 at source.

Anticipate critical scenarios and optimize inspection and maintenance resources.

Organizes and documents all technical processes with traceability and digital backup.

Facilitates technical feedback, risk reassessment and decision making.

Improve asset availability and strengthen the mechanical integrity of your plant.

Our team consists of multidisciplinary engineers with extensive experience in integrity management, risk analysis (RBI), API standards and data analytics. We combine technical knowledge, use of advanced technologies and understanding of industry challenges.

What makes us different?

Vessels, tanks, exchangers, piping and any static plant asset requiring risk-based inspection.

Yes, the software applies methodologies based on API RP 580 and API RP 581, including RAM, RBI and encrypted document management.

It is a practical recommendation developed by the

American Petroleum Institute (API)

that establishes the fundamentals of an effective RBI program, including threat management, risk assessment and data-driven decision making.

It is the complementary document to API 580, which includes the quantitative mathematical models to estimate the risk of equipment failure, including formulas to calculate probability, consequence and frequency.

These are industrial assets that do not have moving parts, such as tanks, pipes, pressure vessels, heat exchangers, etc. They are critical in industrial plants and must be inspected under specific standards.

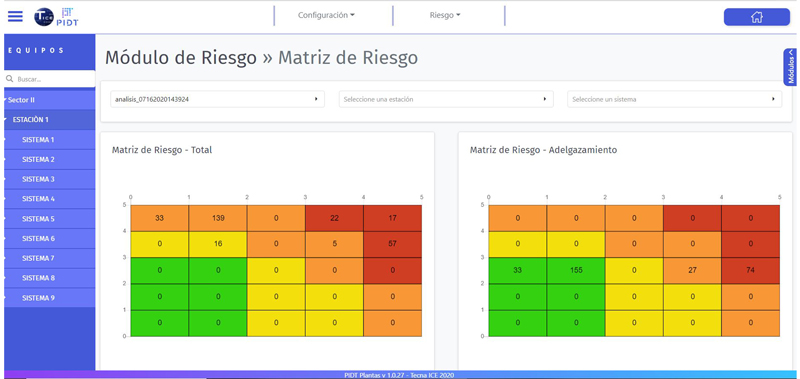

RAM stands for Risk Assessment Matrix. It is a matrix that relates the probability and consequence of failure to categorize the risk level of each asset or system.

RBI stands for Risk-Based Inspection. It is a methodology that prioritizes inspections according to the probability and consequences of failure, optimizing resources and improving integrity management.

Yes, through mobile devices you can perform inspections, record findings, upload evidence and prioritize actions in real time.

Yes, the 3D module allows you to visualize each piece of equipment within the digital model of the plant, with direct access to its data sheet, history and inspections.

Enter your email and leave your data, our team of expert advisors will assist you as soon as possible.

Cathodic protection - Online

Juan Bermudez

Cathodic protection - Online

Juan Bermudez

Assets integrity, NDT Inspections, TECNA GPS Interrupter - Online

Diego Mendoza

Assets integrity, NDT Inspections, TECNA GPS Interrupter - Online

Diego Mendoza

Carbon Footprint, GIS, HSEQ, Process Safety, Risk, Software Dev, Technology - Online

Andrea Acosta

Carbon Footprint, GIS, HSEQ, Process Safety, Risk, Software Dev, Technology - Online

Andrea Acosta

20+ años de experiencia en ingeniería y tecnología en la industria (20+ years of engineer and technology experience in the industry).

Leave your name, email and select the topics you are interested in. We will send you only relevant information, no spam.

Scan this QR code to

view TECNA ICE contacts

Start optimizing your cathodic protection system with our information, consult our experts if you require further information or advice.

Receive expert support to choose the solution that best suits your operation.

Connect with an expert and solve your technical needs accurately.

Receive expert support to choose the solution that best suits your operation.

Receive expert support to choose the solution that best suits your operation.

Request a demo of our PIDT integrity software, or share your requirements. We are ready to support you

Leave us your data and your resume. We will contact you in future selection processes.

Request a quote or send us your requirements. Our technical team is ready to help you.

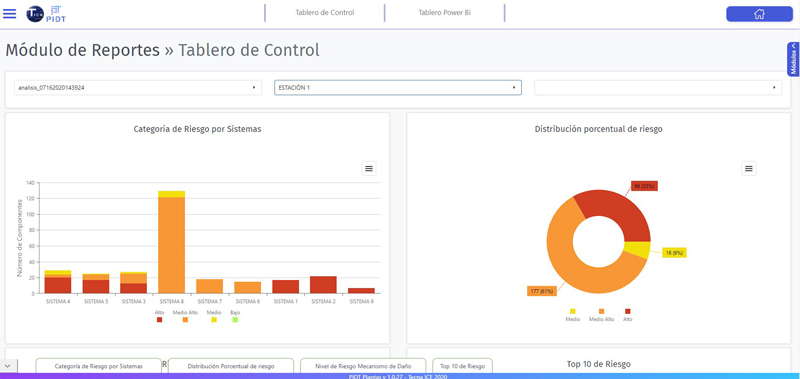

It contains the relevant KPIs to obtain a risk ranking, which are represented by means of dashboards.

Integrates the PIDT Plants with the SCADA tool, in order to calculate the risk, making use of variables such as pressure,

temperature, flow, etc.

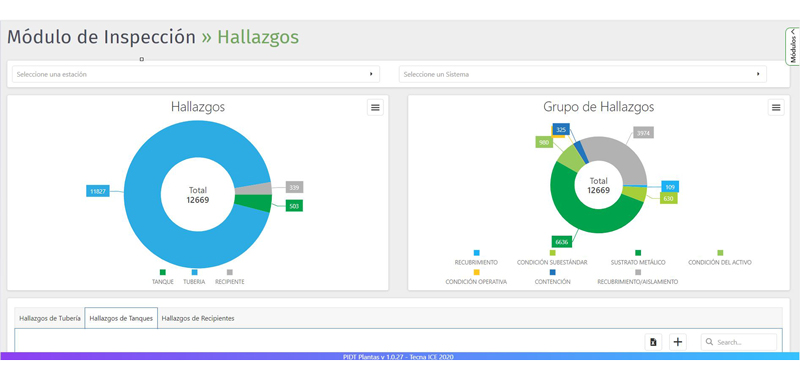

Bulk loading of inspections performed on static equipment, generating an inspection plan derived from RBI and sending SAP alerts.

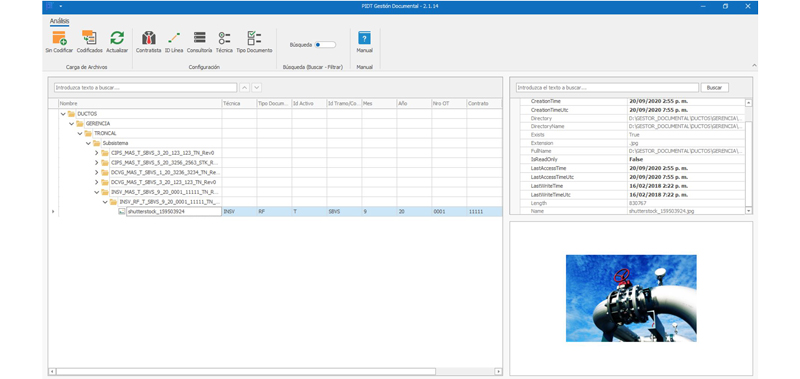

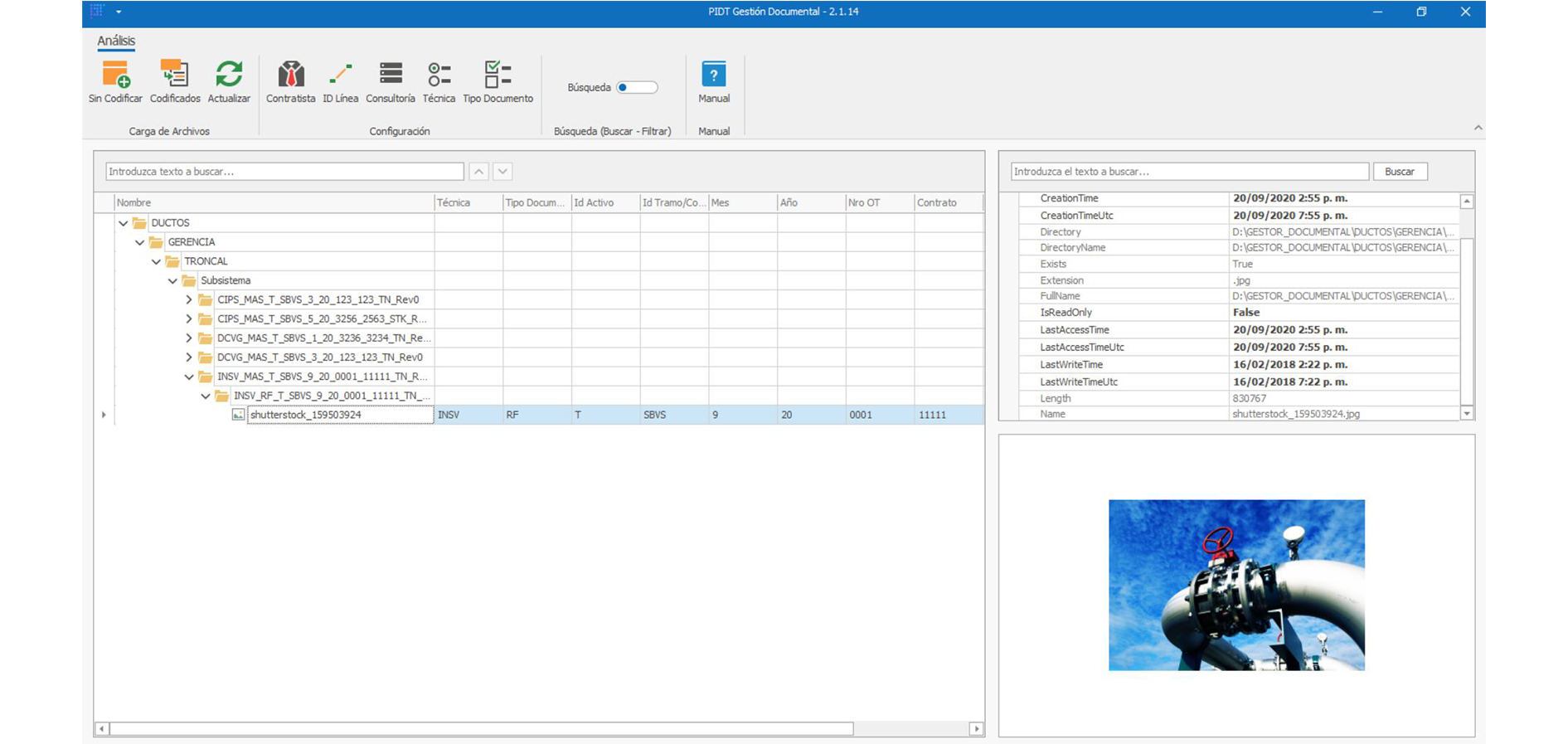

It allows the centralization and codification of the information related to the integrity of the Asset: The necessary nomenclatures are defined in order to identify each document according to its origin. Likewise, each document can be classified in relation to the process in which it is involved. It allows organizing documents by means of a hierarchical tree that enables searches and filters to quickly find documents.

Allows the management, analysis and visualization of information compared to company targets related to:

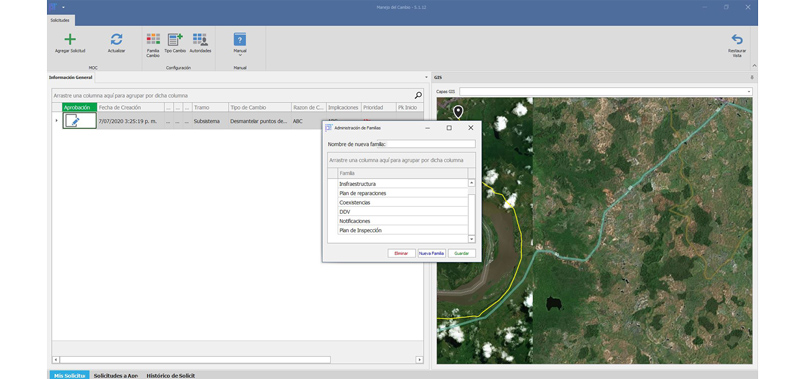

Allows the evaluation and control of modifications to the design of facilities, operation, organization or activities; prior to implementation, in order to ensure that no new elements will be introduced that increase the risk and existing hazards to the business, people or the environment based on applicable regulations.

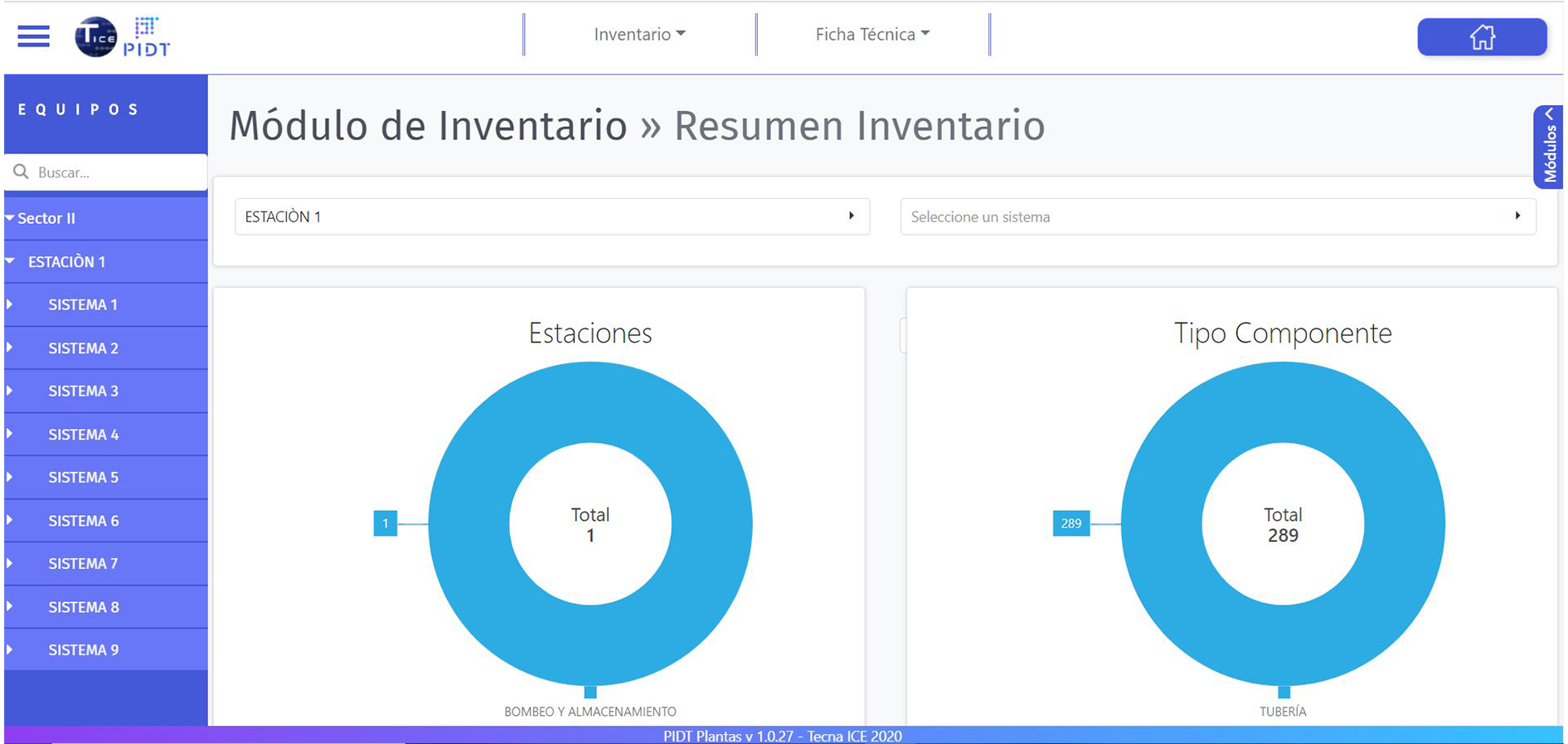

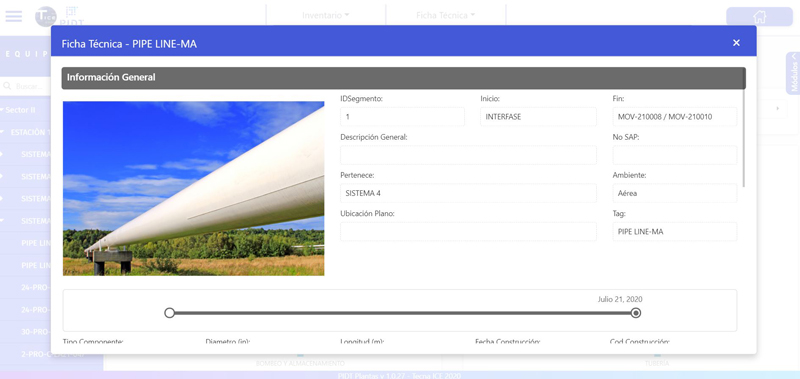

Allows the consultation of information associated with the life cycle of the asset and its accessories.

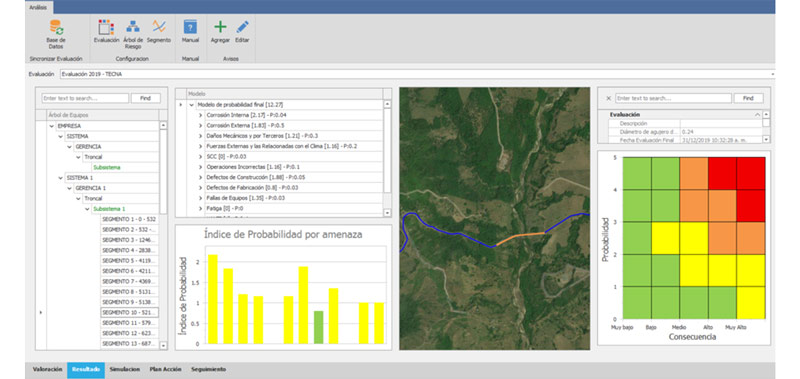

Assesses and analyzes the risk level of the Assets to generate an inspection plan. It is designed to perform the calculation and analysis of static equipment risk under the RP API 581-16 standard. The user will be able to create the required risk assessments

to generate a valuation and inspection plan.

It allows the centralization and codification of the information related to the integrity of the Asset: The necessary nomenclatures are defined in order to identify each document according to its origin. Likewise, each document can be classified in relation to the process in which it is involved. It allows organizing documents by means of a hierarchical tree that enables searches and filters to quickly find documents.