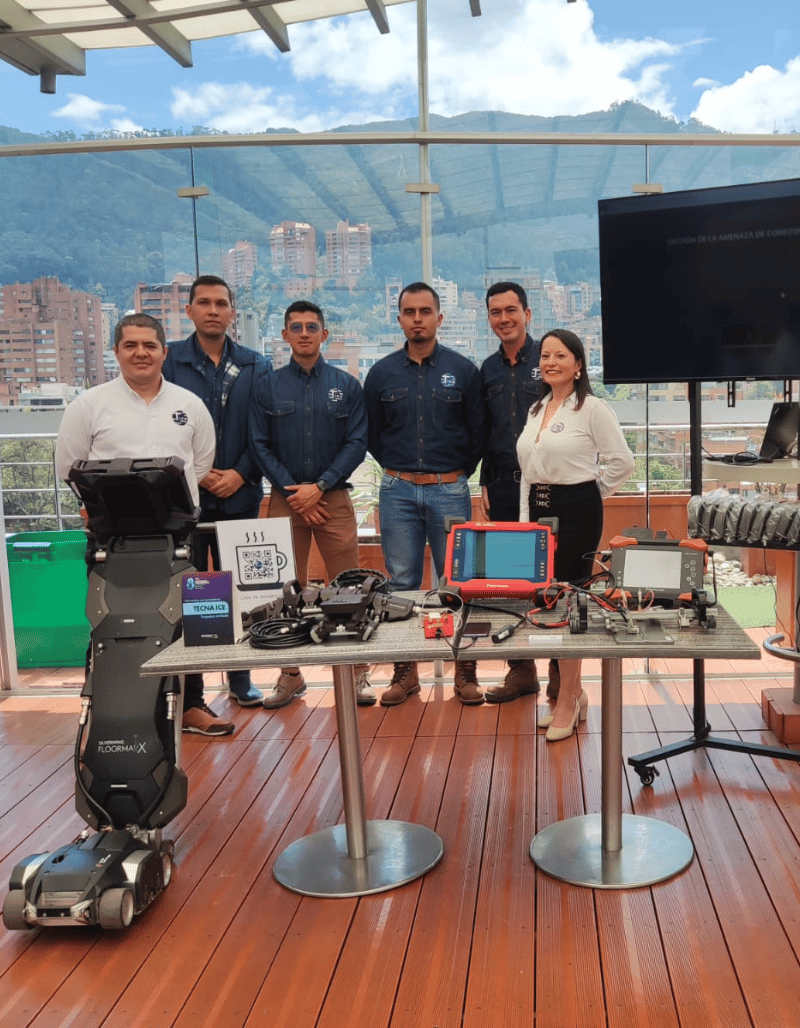

// Integrity Management

Ultrasonic Testing Inspection

Ultrasonic testing inspection for accurate weld and corrosion detection.

At TECNA ICE, we provide ultrasonic testing inspection services using Phased Array Ultrasonic Testing (PAUT) and Time-of-Flight Diffraction (TOFD), offering unmatched accuracy and efficiency.