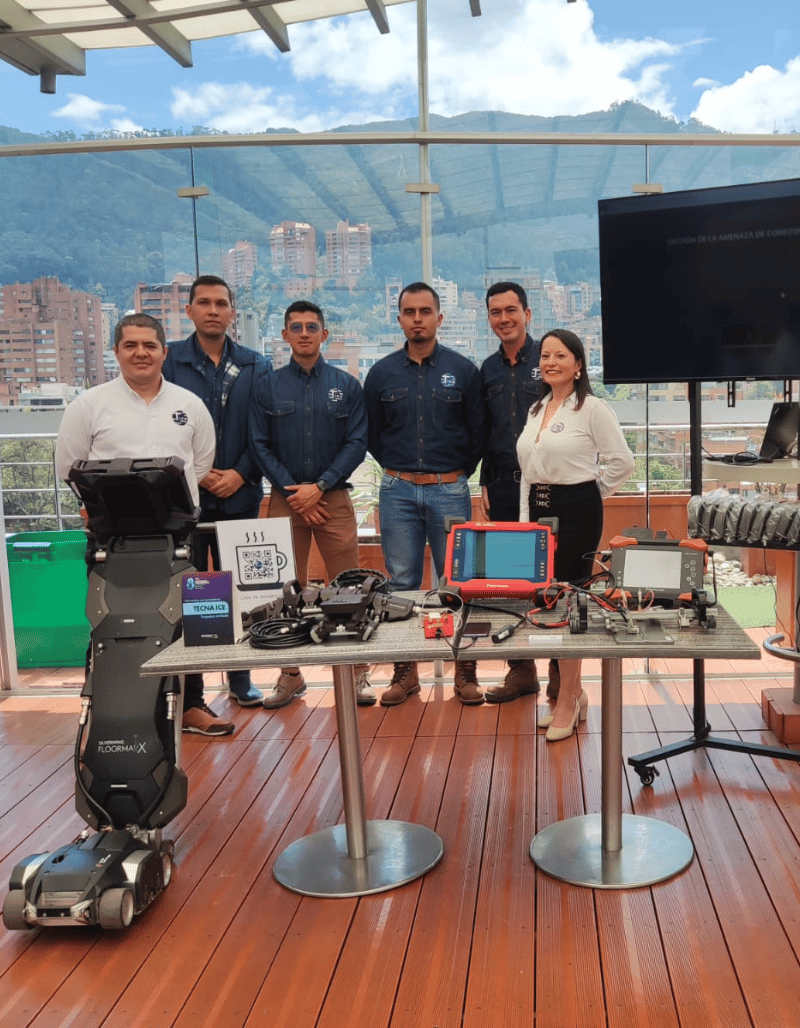

// Tank Floor Inspection

MFL Tank floor inspection for proactive asset integrity

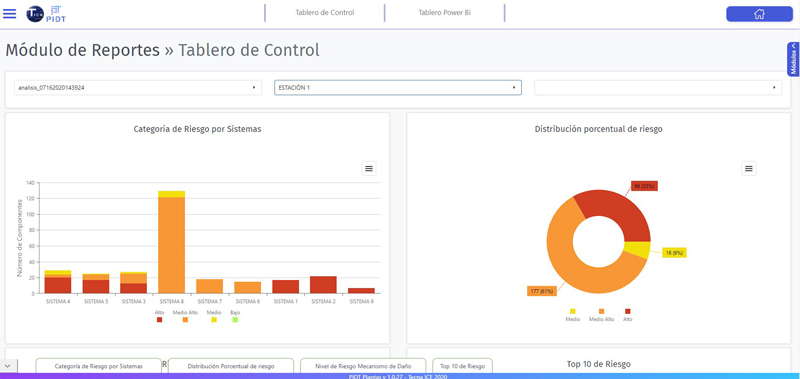

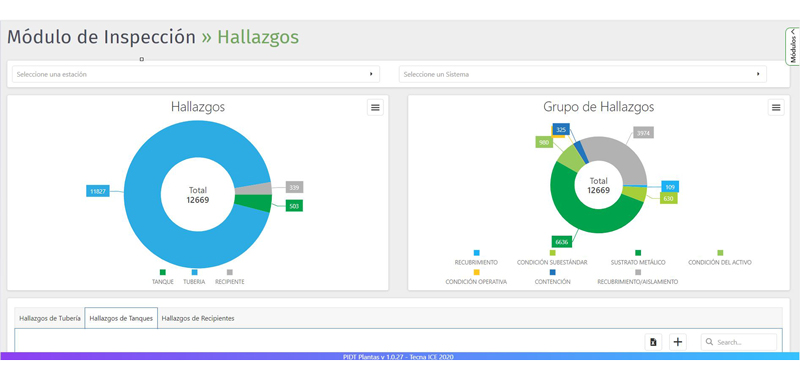

Tank floor inspection is critical to ensuring the operational safety and long-term durability of your storage infrastructure. At TECNA ICE, we use Magnetic Flux Leakage (MFL) technology with Floormap X to detect and map corrosion—before it causes costly damage or non-compliance.