// Integrity Management

High Precision 3D Scanner

At TECNA ICE, we provide state-of-the-art high precision 3D scanner services to inspect and model industrial infrastructure.

Conventional inspection methods often fall short when it comes to capturing the actual condition of critical assets. Without accurate 3D data, it’s nearly impossible to understand the full extent of surface corrosion or mechanical damage.

This lack of insight can lead to costly downtime, unplanned repairs, and compromised safety.

Our service uses the PEEL 3D handheld scanner—a professional-grade tool designed for high-accuracy data capture.

Key capabilities:

Dents, wrinkles, external corrosion, and plastic deformations

Works on pipes, tanks, and any surface material

Intuitive operation without complex processes.

Immediate digital registration and analysis

Captures complex geometries accurately

Scan objects from 0.1 to 3 meters

CSV export and 3D mesh for advanced technical documentation.

API 579, ASME B31, ASTM

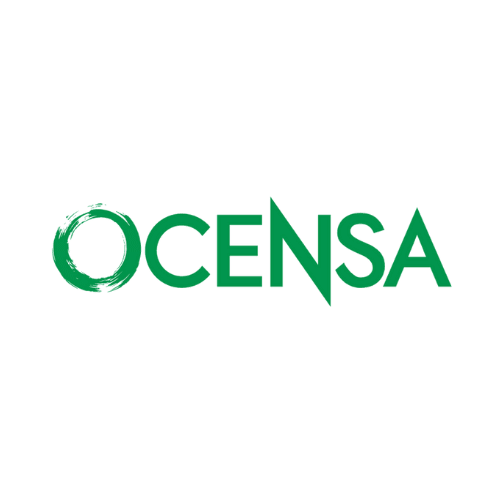

For our client OCENSA, we implemented a comprehensive 3D laser scanning inspection service for integrity management, ensuring the optimal operation and safety of its infrastructure.

State-of-the-art technology backed by highly trained talent. At TECNA ICE we have a team of professionals specialized in inspection and integrity management, certified in the most demanding industry standards:

Not necessarily. In most cases, scanning can be performed without interrupting operations, as it is a non-contact method that does not affect the integrity of the inspected assets.

The scanner used offers millimeter accuracy, allowing highly reliable assessment of defects such as external corrosion, dents and deformations.

3D laser scanning focuses on capturing the external geometry with high accuracy, generating detailed digital models. Methods such as ultrasound or radiography detect internal defects, so both approaches can be complementary in a complete evaluation.

PEEL 3D is a professional-grade handheld scanner that combines high accuracy, ease of use and versatility. Its ergonomic design allows complex surfaces to be scanned in real time, capturing details with an accuracy of up to 0.1 mm. In addition, it supports multiple export formats, making it easy to integrate with analysis and inspection software.

Enter your email and leave your details, our expert advisors in integrity and asset management will get back to you as soon as possible.

Integridad, Interruptor TECNA, Protección Catódica - Online

Diego Mendoza

Integridad, Interruptor TECNA, Protección Catódica - Online

Diego Mendoza

Huella de carbono, Riesgos, Seguridad de procesos, Servicios GIS, Software de Integridad, Software HSEQ, Software seguridad de procesos, Tecnología - Online

Andrea Acosta

Huella de carbono, Riesgos, Seguridad de procesos, Servicios GIS, Software de Integridad, Software HSEQ, Software seguridad de procesos, Tecnología - Online

Andrea Acosta

20+ años de experiencia en tecnología para el sector Energético.

Start optimizing your cathodic protection system with our information, consult our experts if you require further information or advice.

Receive expert support to choose the solution that best suits your operation.

Connect with an expert and solve your technical needs accurately.

Receive expert support to choose the solution that best suits your operation.

Receive expert support to choose the solution that best suits your operation.

Request a demo of our PIDT integrity software, or share your requirements. We are ready to support you

Request a quote or send us your requirements. Our technical team is ready to help you.

Leave us your data and your resume. We will contact you in future selection processes.

Leave your name, email and select the topics you are interested in. We will send you only relevant information, no spam.

Scan this QR code to

view TECNA ICE contacts

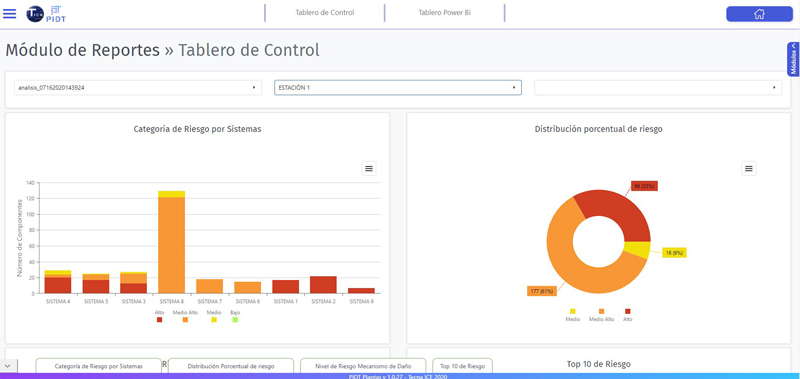

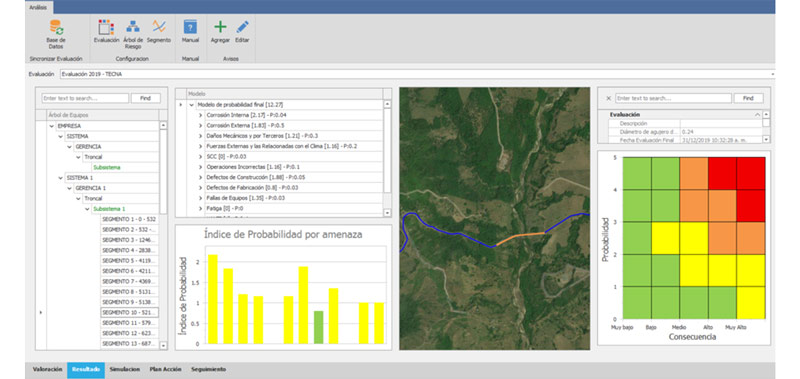

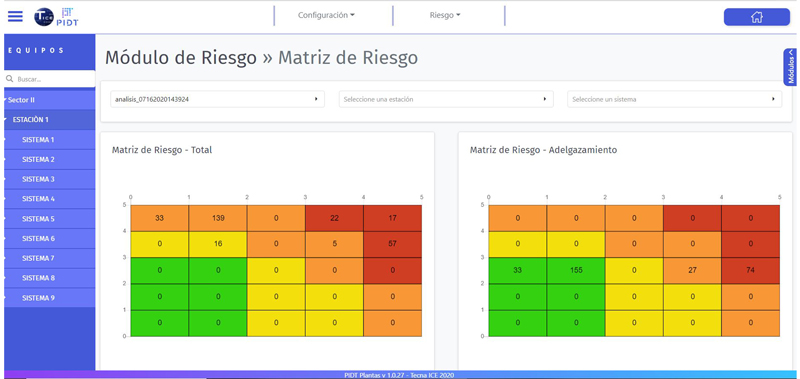

It contains the relevant KPIs to obtain a risk ranking, which are represented by means of dashboards.

Integrates the PIDT Plants with the SCADA tool, in order to calculate the risk, making use of variables such as pressure,

temperature, flow, etc.

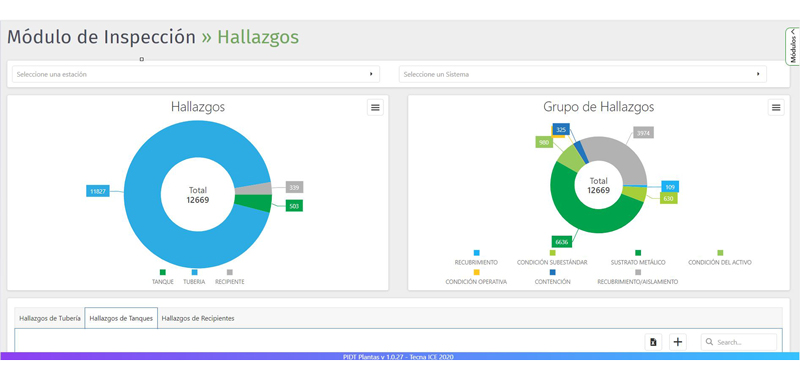

Bulk loading of inspections performed on static equipment, generating an inspection plan derived from RBI and sending SAP alerts.

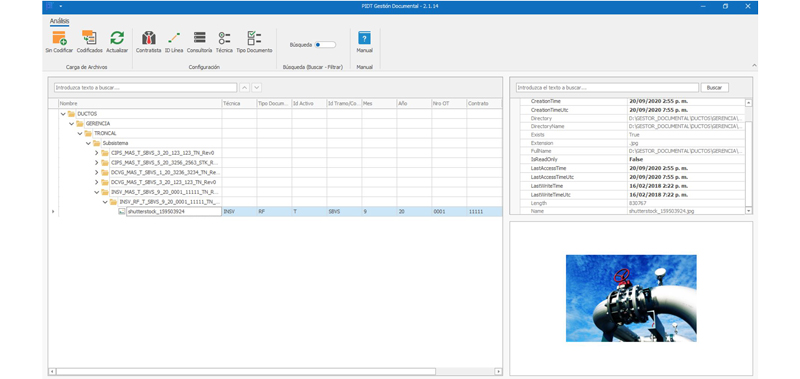

It allows the centralization and codification of the information related to the integrity of the Asset: The necessary nomenclatures are defined in order to identify each document according to its origin. Likewise, each document can be classified in relation to the process in which it is involved. It allows organizing documents by means of a hierarchical tree that enables searches and filters to quickly find documents.

Allows the management, analysis and visualization of information compared to company targets related to:

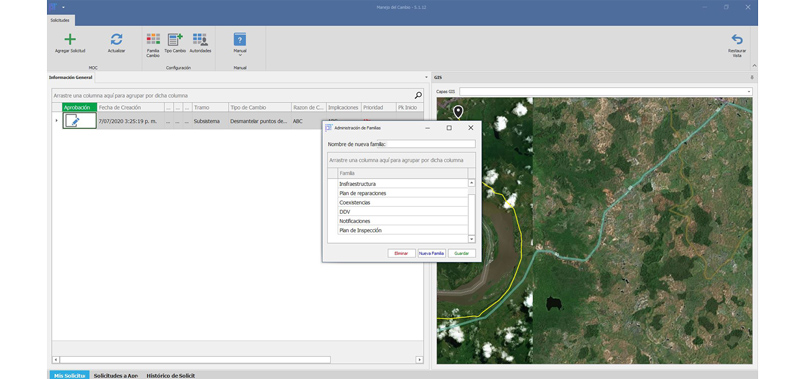

Allows the evaluation and control of modifications to the design of facilities, operation, organization or activities; prior to implementation, in order to ensure that no new elements will be introduced that increase the risk and existing hazards to the business, people or the environment based on applicable regulations.

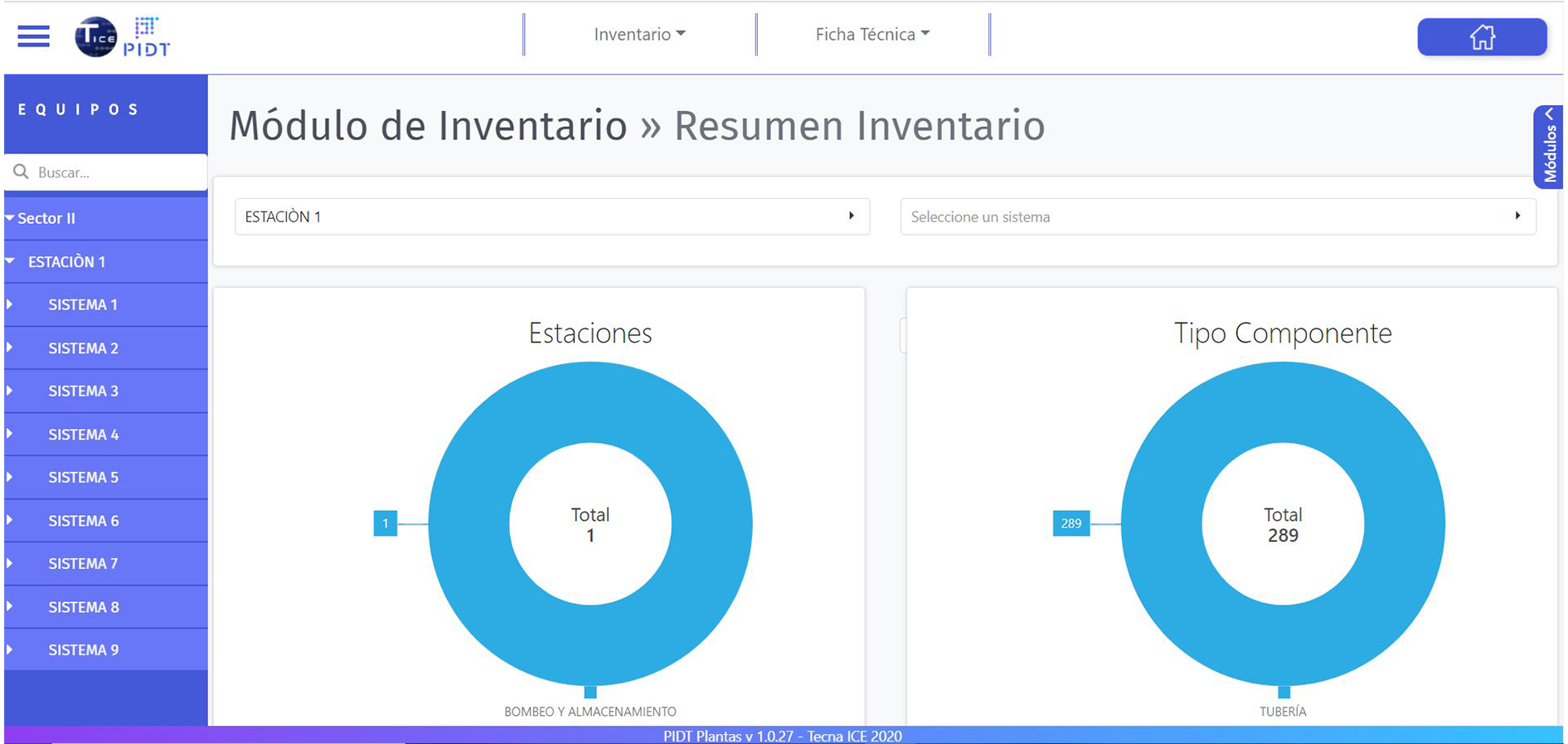

Allows the consultation of information associated with the life cycle of the asset and its accessories.

Assesses and analyzes the risk level of the Assets to generate an inspection plan. It is designed to perform the calculation and analysis of static equipment risk under the RP API 581-16 standard. The user will be able to create the required risk assessments

to generate a valuation and inspection plan.

It allows the centralization and codification of the information related to the integrity of the Asset: The necessary nomenclatures are defined in order to identify each document according to its origin. Likewise, each document can be classified in relation to the process in which it is involved. It allows organizing documents by means of a hierarchical tree that enables searches and filters to quickly find documents.