We have personnel from multiple engineering disciplines with experience in integrity management, reliability and specialized inspection, with international certifications API, ASME, ASNT, AMPP, PMI, SMRP among others.

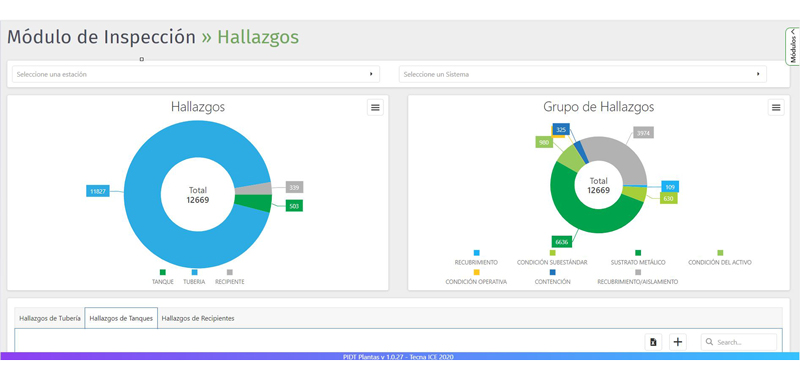

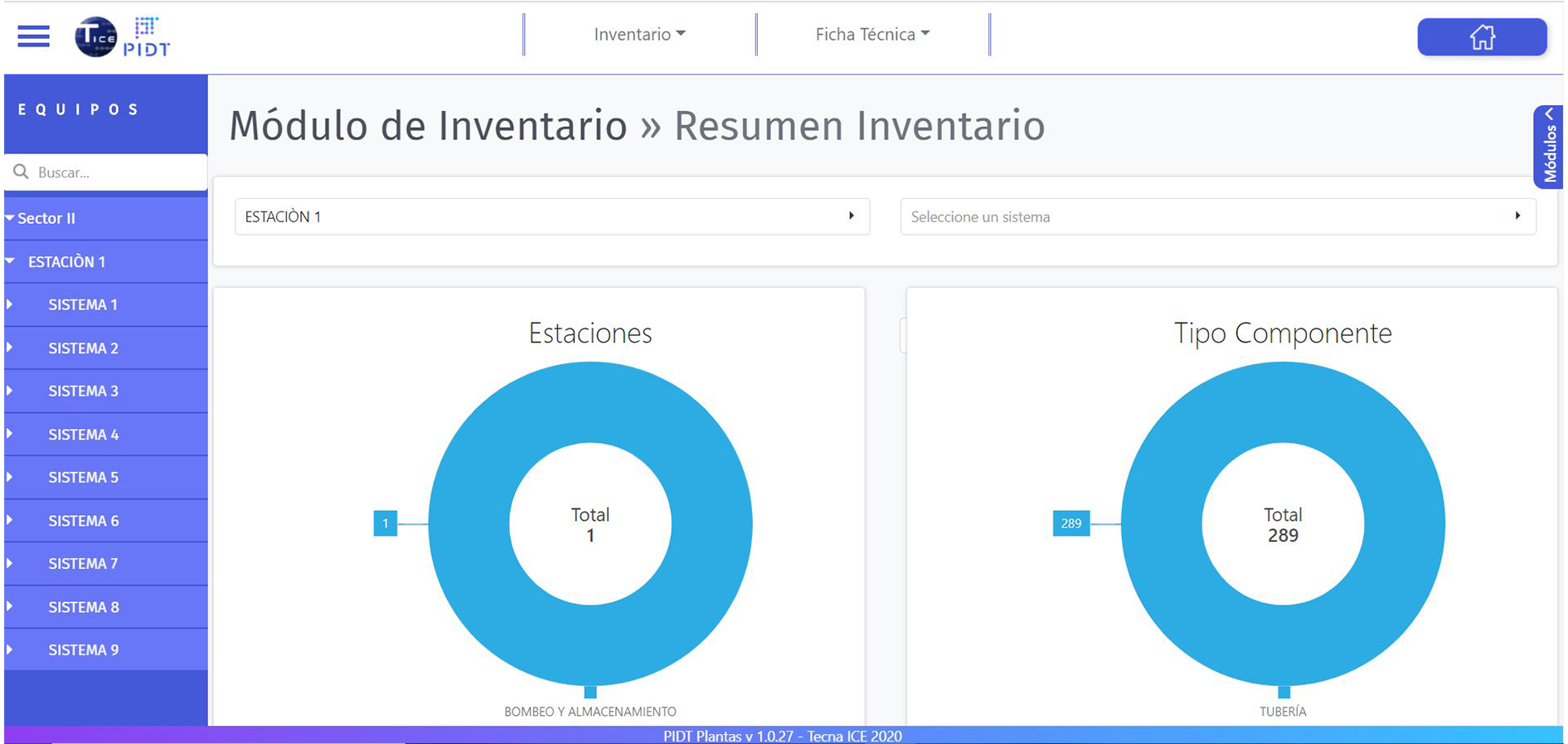

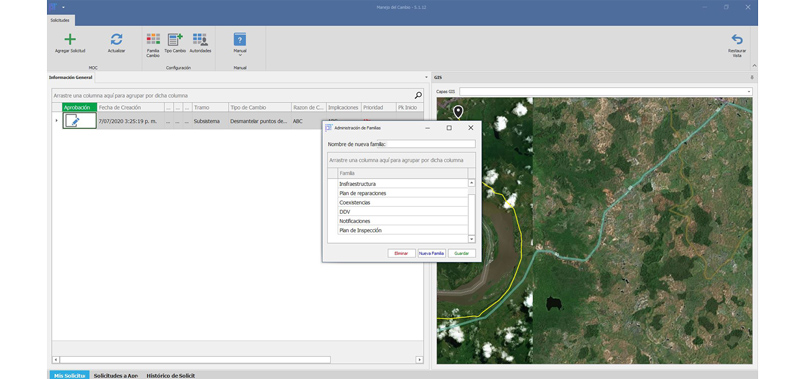

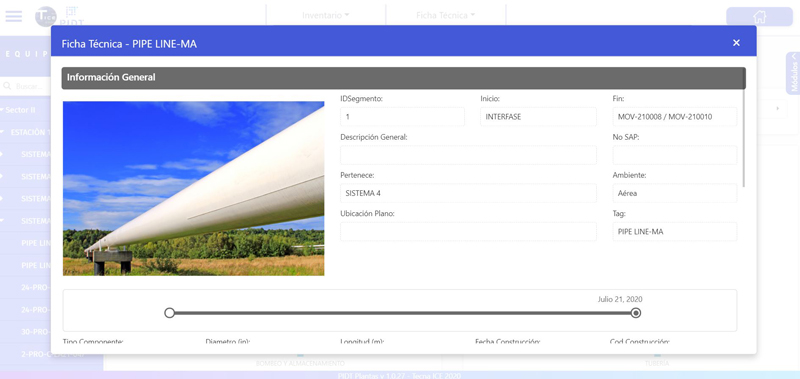

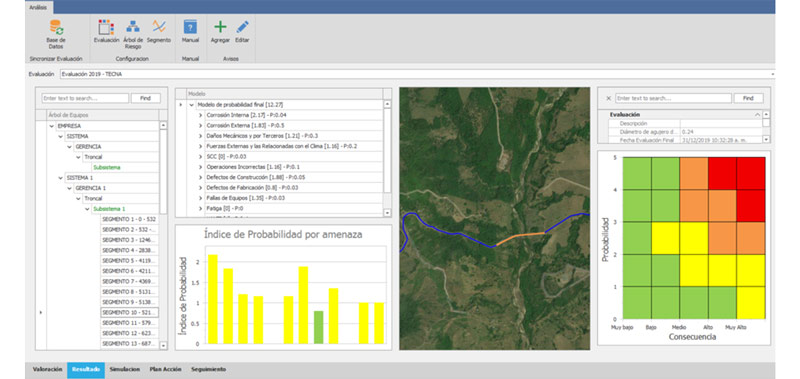

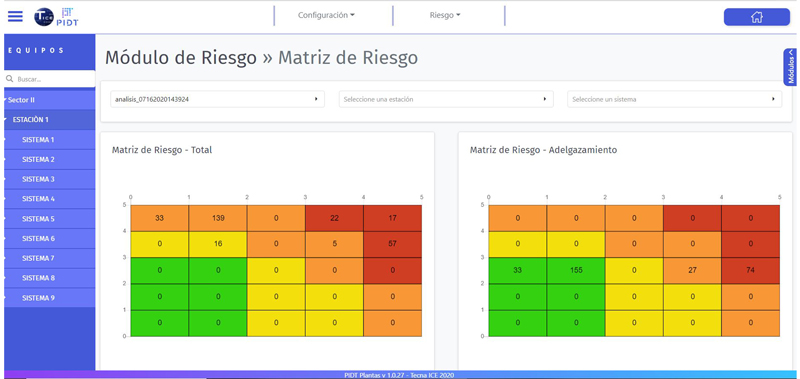

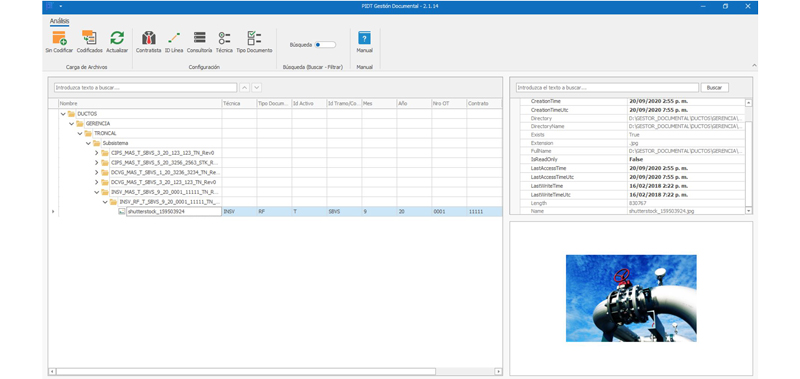

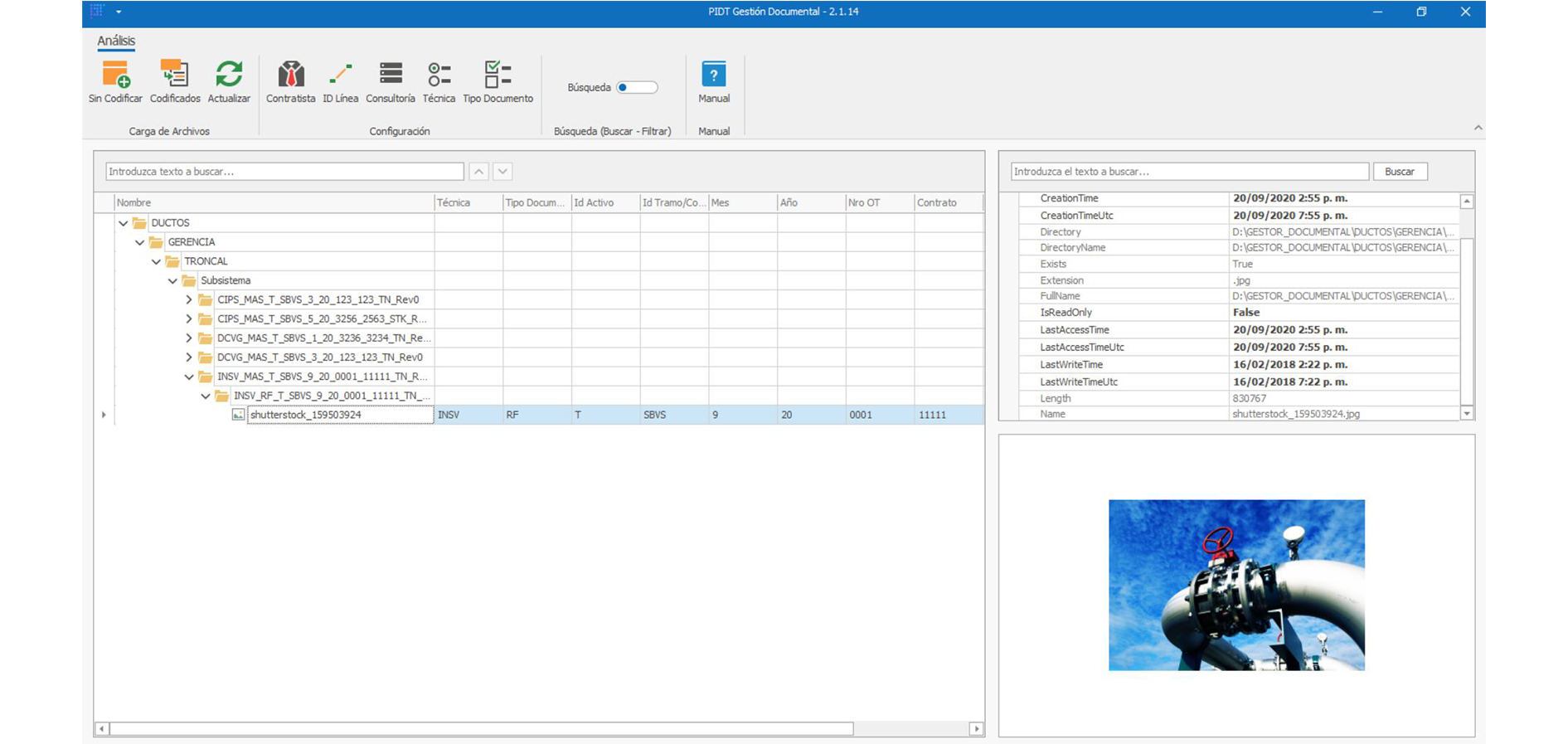

Extensive experience developing projects for integrity planning and management, inspection and maintenance plans, based on risk assessment and the recommendations of international standards and industry best practices. We also perform integrity assessments for both external corrosion (ECDA) and internal corrosion (ICDA), according to AMPP (NACE) standards.

The international standards that provide the basis for the construction of integrity management plans are: API 1160, ASME B31.8s, DOT, CAN-CSA Z662, among others, allow us to make the right decisions ensuring the highest level of integrity of equipment, tanks, pipes, pipelines, ducts and transportation systems.

List of Non Destructive Testing and Inspection Techniques

We perform certified inspections of equipment, tanks and facilities and inspections for fitness for service evaluation.

We perform inspection and non-destructive testing by ultrasound, magnetic techniques, specialized and conventional techniques such as SCAN A/B/C, Phased Array, Guided Wave, MFL, LFET, EMAT, Acoustic Emission, Eddy Current, including defectology evaluations and failure analysis.

- Visual Inspection

- UT SCAN A/B/C/S

- Defectology and Failure Analysis

- Guided Wave

- MFL, LFET and EMAT

- Acoustic Emission

Boroscopy, fiberscopy and videoscopy

- Conventional Radiography and Digital Radiography

- Magnetic particles, penetrating liquids/dyes

- Eddy Currents

- Positive material identification, metallography, metallographic replicates and hardness

- Thermography and LIDAR (Point Cloud)

Coating inspection and evaluation, coating thickness measurement

- Holiday and adhesion tests.

We have expert personnel, on-site sampling equipment and services and specialized laboratories for internal corrosion monitoring, including:

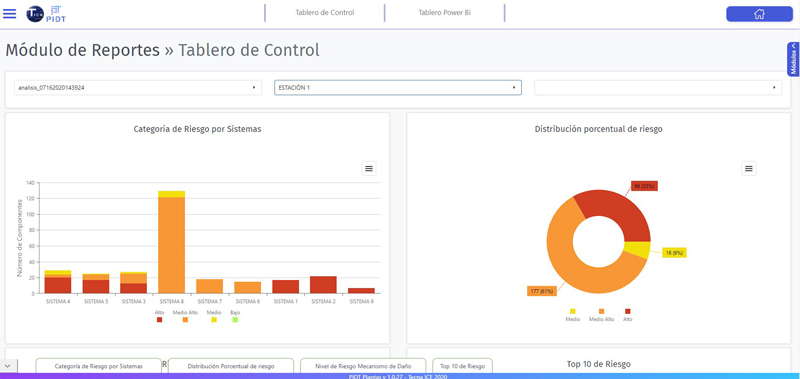

Integrity Management Plan

Integrity Management Plan Internal Corrosion Monitoring

Internal Corrosion Monitoring