Decree 1347 of 2021 is part of the Sole Regulatory Decree of the Labor Sector in Colombia and establishes the guidelines for the adoption of the Major Accident Prevention Program (PPAM). This decree seeks to strengthen risk management in facilities where hazardous substances are handled, promoting a culture of prevention, control and mitigation of major accidents.

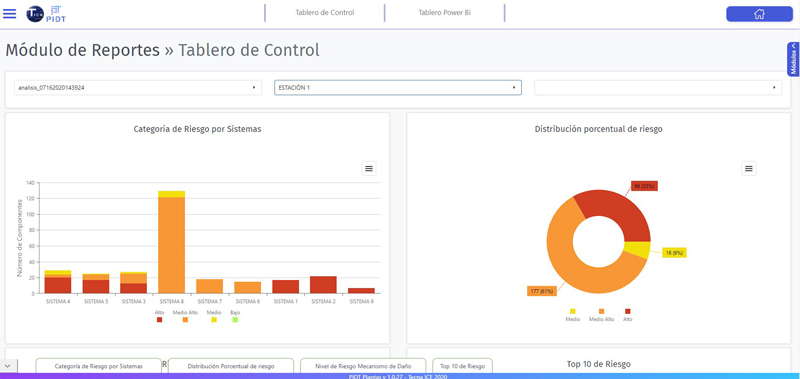

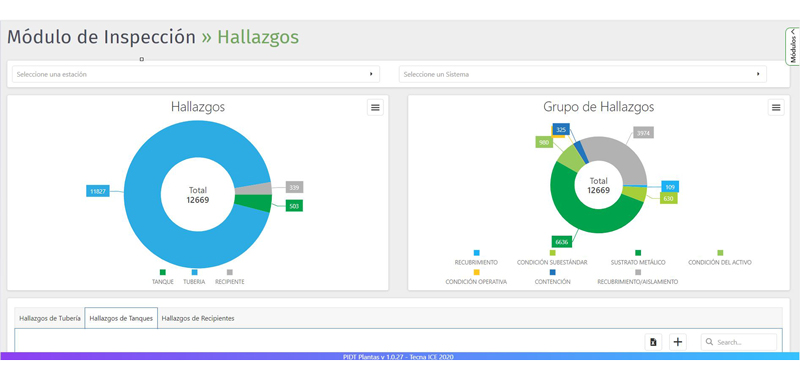

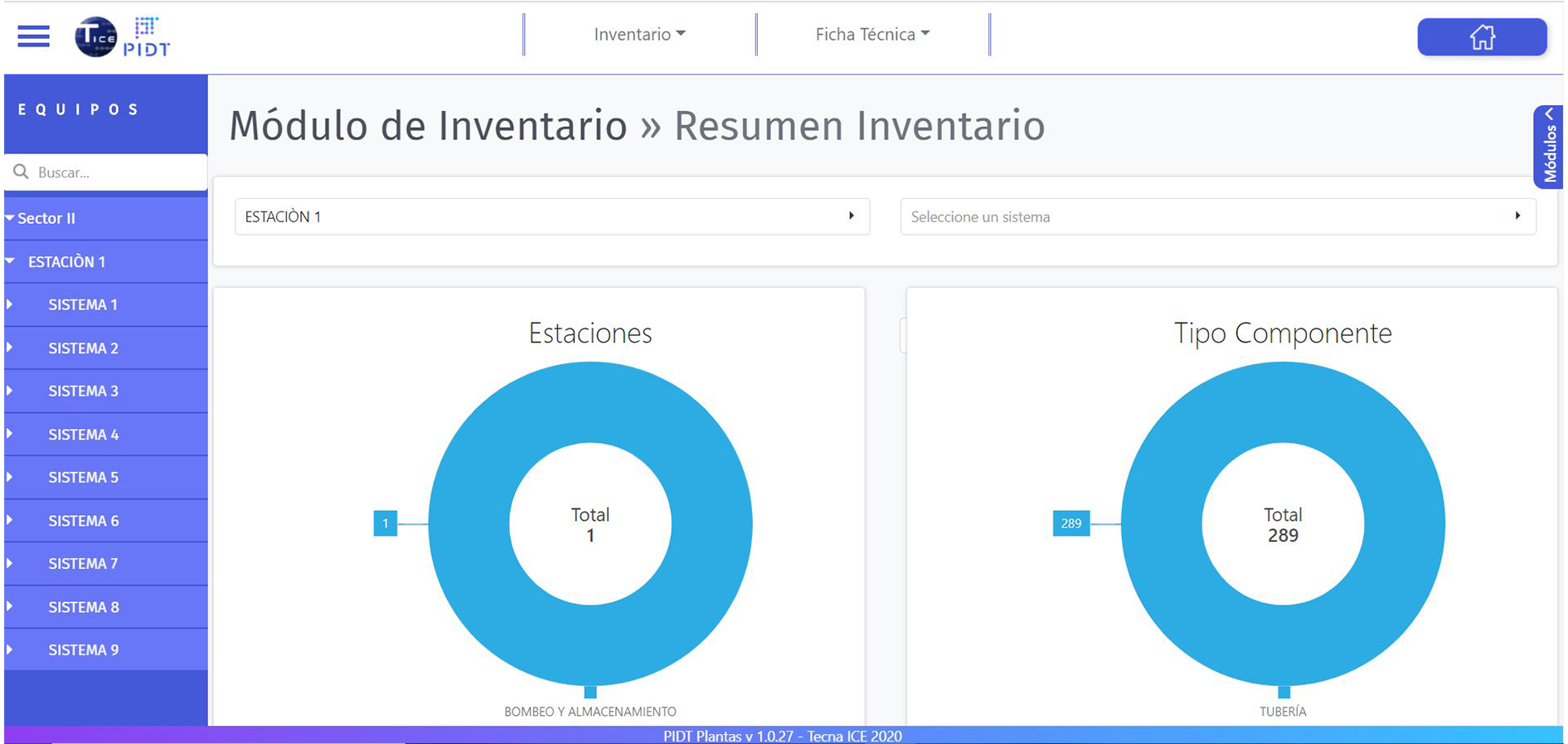

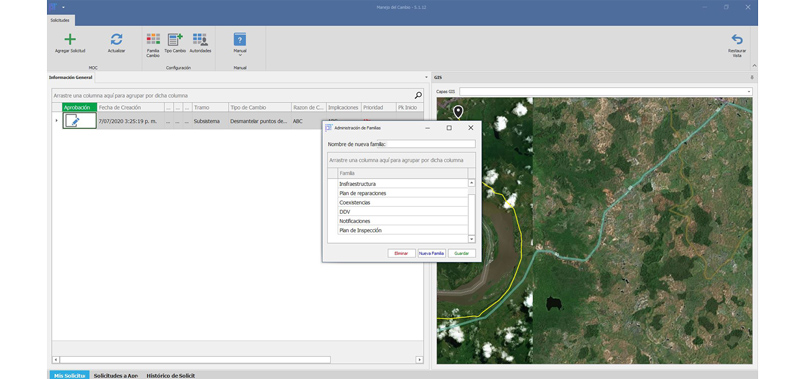

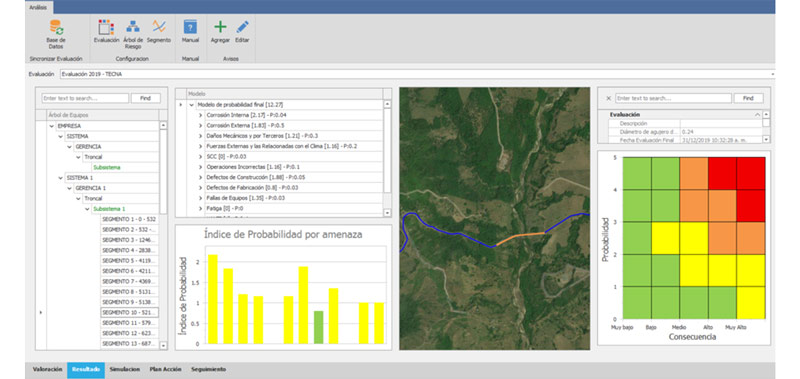

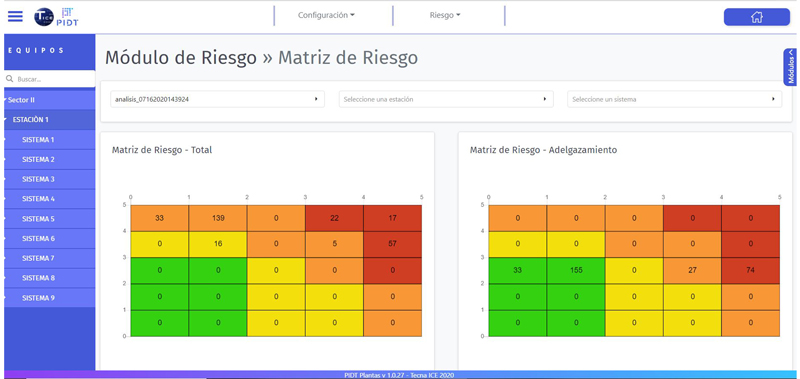

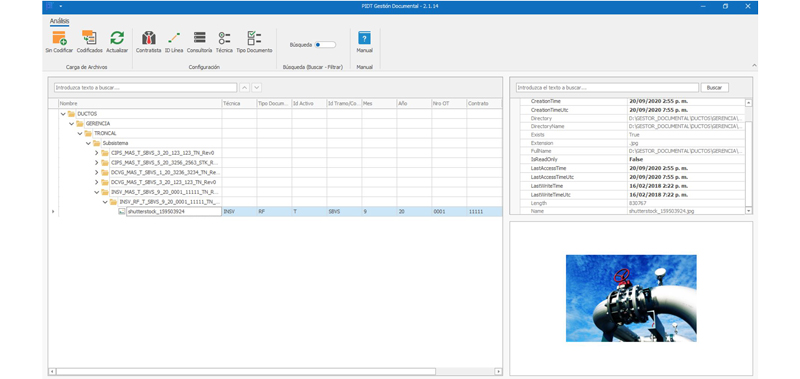

The PPAM requires companies to diagnose the level of process safety maturity, identify gaps and establish an action plan to close them, integrating tools such as risk analysis, technical inspections and monitoring of operating conditions. At Tecna ICE we support this implementation with specialized solutions and regulatory consulting.