Since 2021, Colombia took a fundamental step in industrial risk management with the adoption of Decree 1347, which establishes the Major Accident Prevention Program (PPAM). This regulation, which amends Decree 1072 of 2015, seeks to protect life, the environment and infrastructure in facilities that handle hazardous chemicals. What does this imply for those responsible for […]

Corrosion is a silent enemy that can compromise the integrity of metallic structures and generate substantial economic losses. Cathodic protection systems are an effective solution to combat this problem, with current interrupters playing a key role in performance evaluation. What is a cathodic protection current Interrupter, and why is it important? A cathodic protection current […]

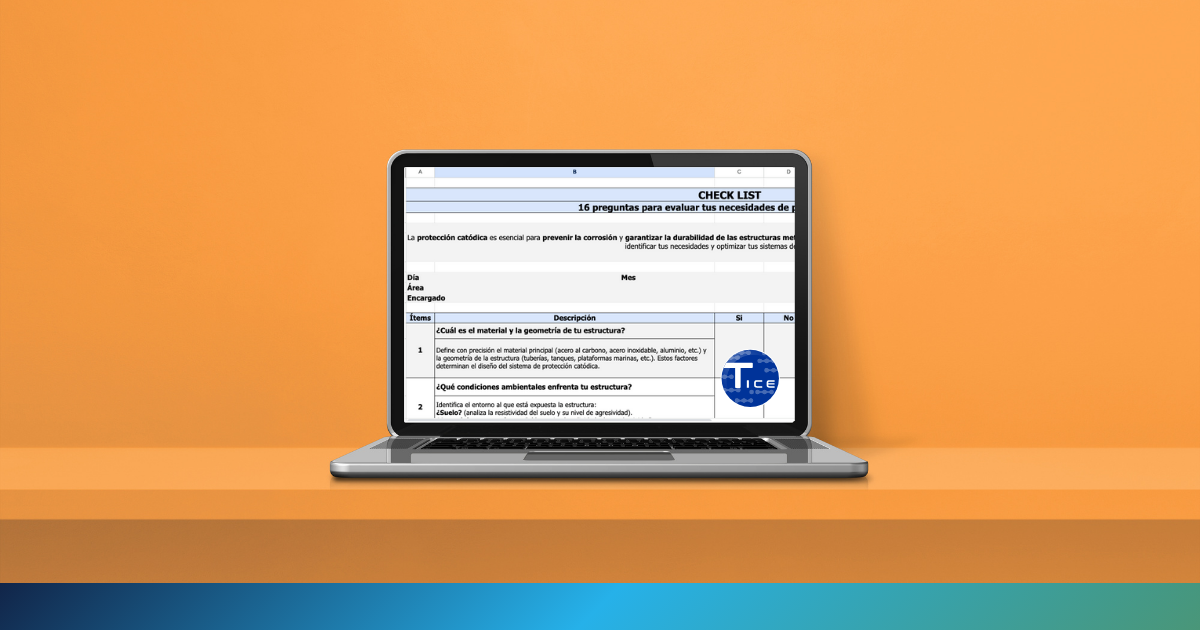

Cathodic protection is a critical component in the prevention of corrosion in industrial infrastructure. With the constant advancement of technology and best practices, it is essential for engineers, managers and consultants to stay current on the latest trends in this field. In this article, we will explore five current trends in cathodic protection that are […]

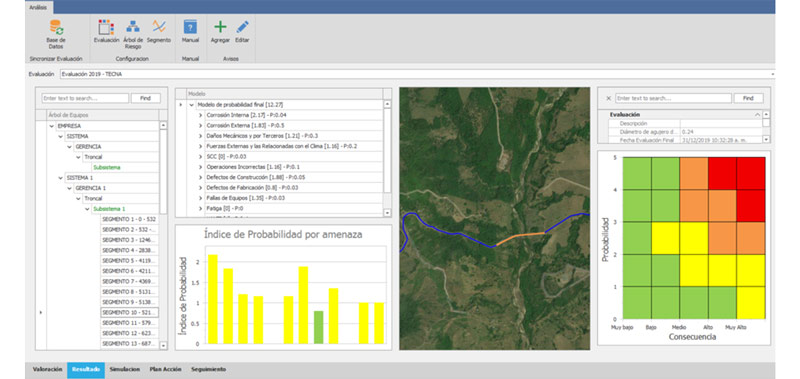

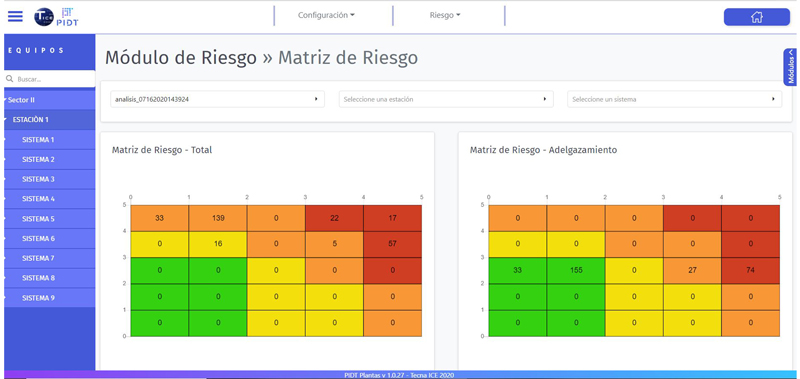

In the field of integrity engineering and cathodic protection, making strategic decisions based on accurate data is essential to prevent failures in critical infrastructure such as pipelines, industrial plants, and storage systems. But how can you ensure your strategies are truly effective? Asset optimization relies not only on experience but also on advanced tools that […]

Cathodic protection is a proven method for extending the service life of metallic infrastructures in corrosive environments. While the CP system is essential for protection, the current interrupter is a key inspection tool used to accurately evaluate and verify system performance. This article provides detailed technical guidance on how to select the ideal current interrupter, […]

Advanced current interrupter technology is transforming the way cathodic protection (CP) inspections are performed on pipelines, storage tanks, and other critical assets. The use of an advanced current interrupter not only improves inspection accuracy, but also enhances system reliability and ensures compliance with international standards. What is a Current Interrupter for CP Inspections? A current […]

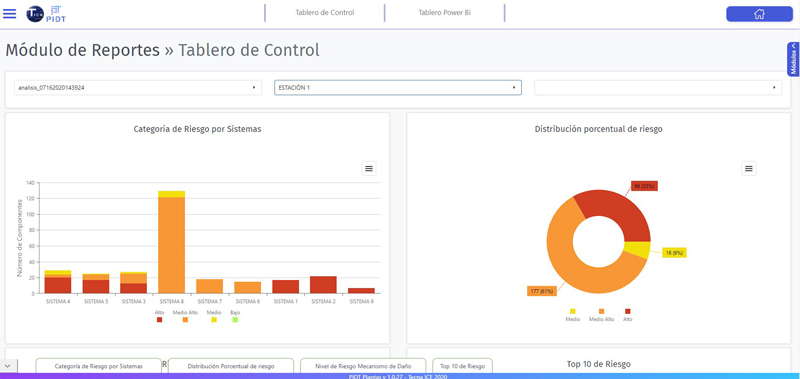

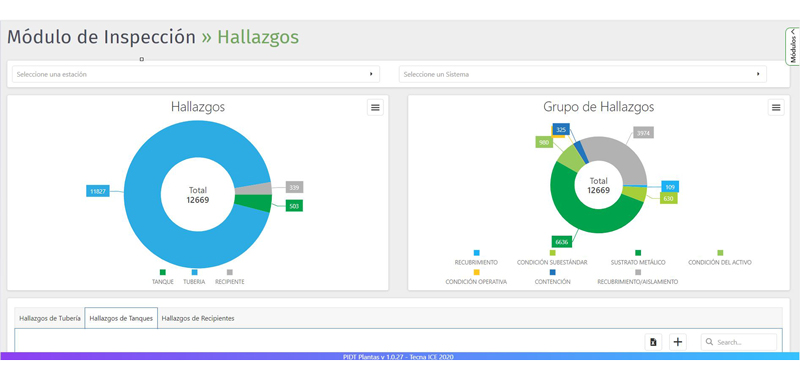

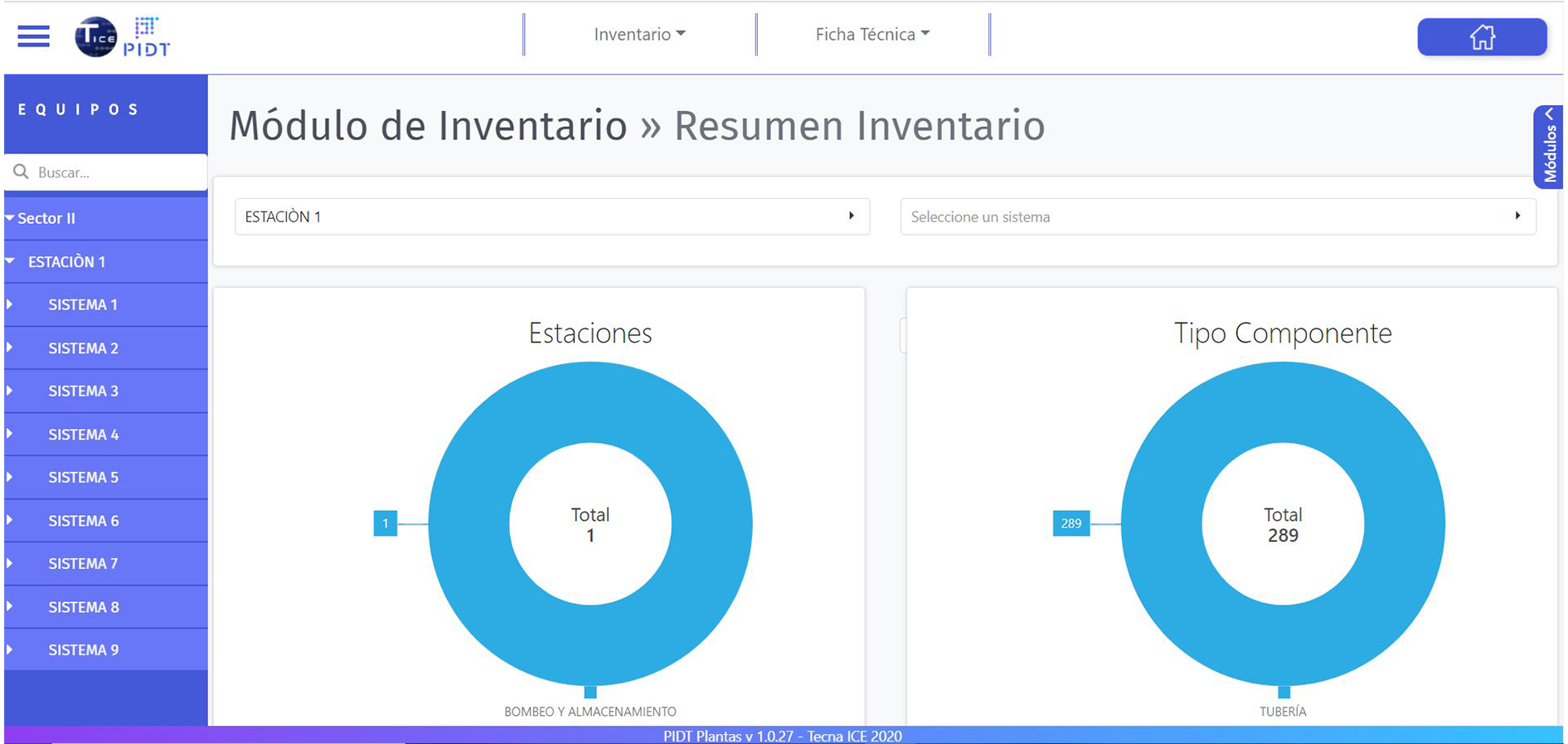

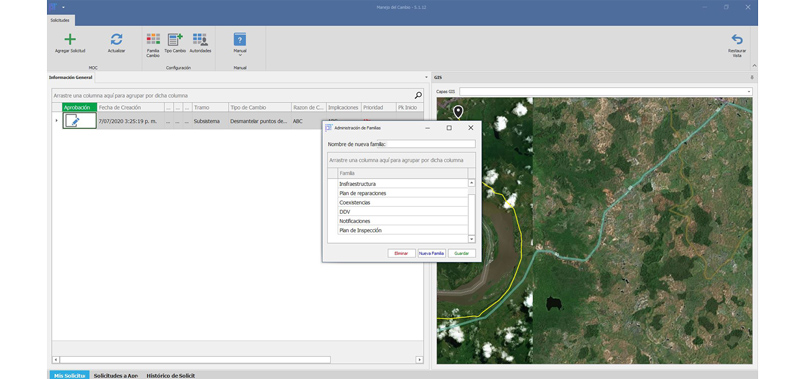

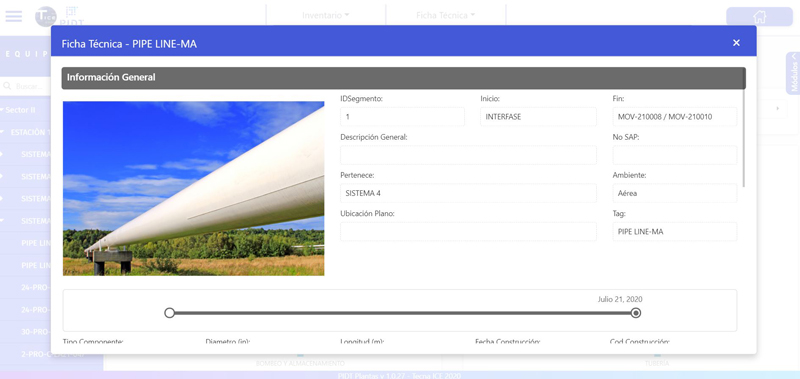

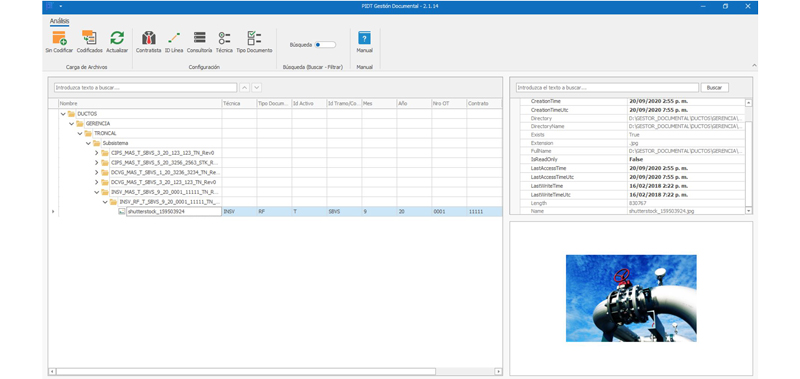

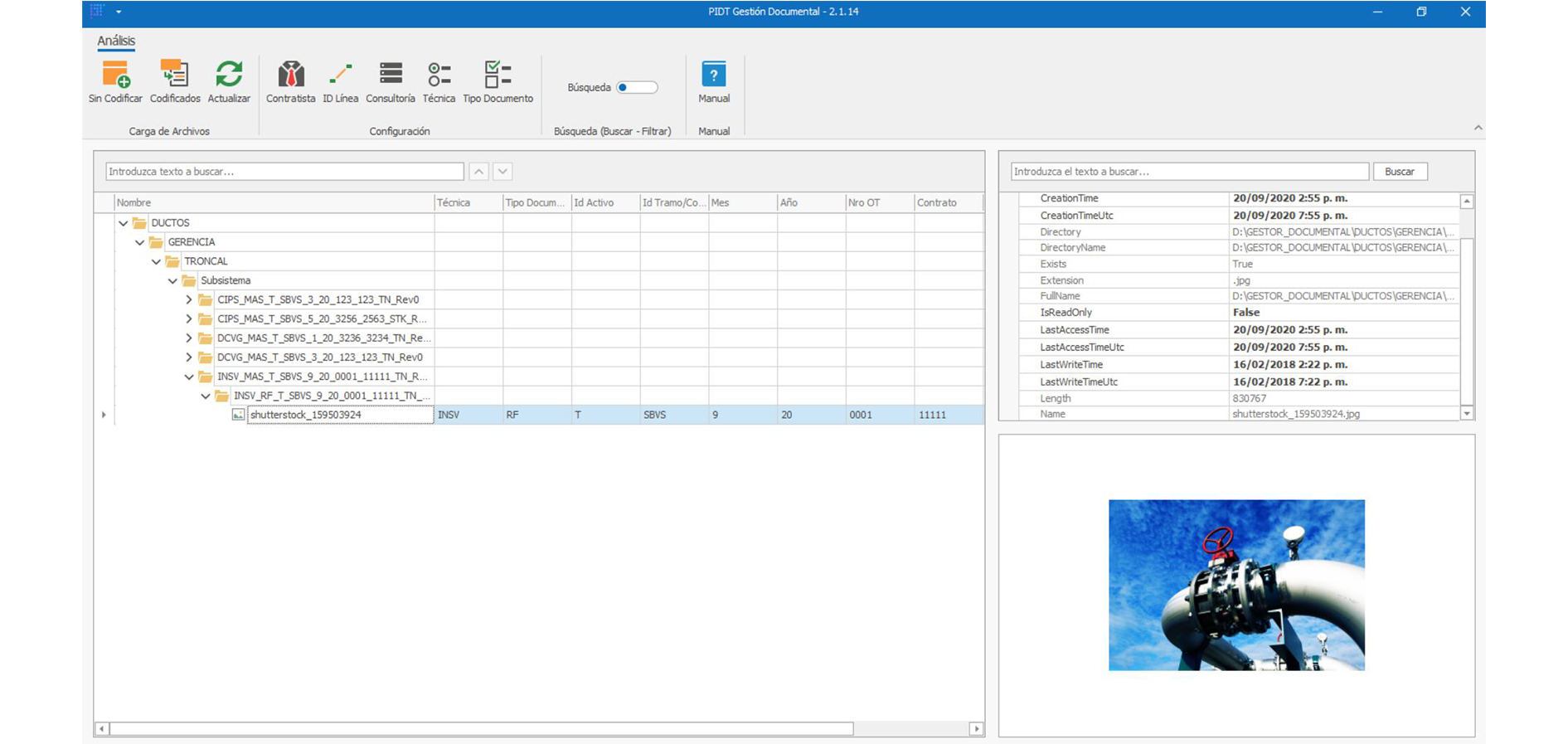

Maximice el rendimiento, optimice los presupuestos de mantenimiento y garantice la seguridad a largo plazo mediante la implementación de mejores prácticas de gestión de datos en toda la empresa con nuestro software para integridad de ductos PIDT. El conjunto de soluciones de administración de integridad de tuberías ayuda a los operadores a integrar grandes cantidades […]

Sacrificial anodes are elements that are installed in pipes or tanks so that the whole system is free of corrosion, when they are implemented they displace all the corrosion towards them and thus protect the metal. In order to generate this effect, the materials to be used must be pure, such as zinc, magnesium or […]

Myth: off-shore wind energy is not a viable renewable energy option. Reality: Offshore wind has been around for about 20 years and has become an important part of the energy mix in the developed countries of the world. Some of the best wind resources in the United States are offshore, which have the added benefit […]