Preventing metal corrosion: types, causes and effective solutions

There are companies whose operations depend on metal infrastructure that must be protected from corrosion to ensure proper functionality. Ongoing research and advances in coatings, cathodic protection, non-destructive testing, analysis and inhibitors enable companies to operate safely and consistently.

What types of corrosion are there?

General Corrosion (uniform)

It occurs relatively uniformly on the surface of a metal. When calculating the operating pressure, the gradual retreat of the wall thickness of the component must be taken into account.

Localized Stings

It causes the formation of small cavities or fissures on the surface of the material. Although close visual inspection is required to detect them, cracks can grow inward enough to perforate the pipe wall.

Localized Interstitial Corrosion

Gaps are virtually impossible to avoid in pipe installations, and when they are very narrow they pose the greatest risk of corrosion.

Stress Corrosion

Stress corrosion cracking (SCC) is dangerous because it can destroy a component at stress levels below the tensile strength of an alloy.

Hydrogen Weakening

Hydrogen-induced cracking can occur if the metal is subjected to static or cyclic tensile stress. Hydrogen can cause changes in the mechanical properties and behavior of the metal

Intergranular Corrosion

Think of all metals as being made up of loose grains. Intraregular corrosion attacks the material along the grain boundaries (where the grains that form the metal meet).

Galvanic Corrosion

This is produced when two metals are in electrical contact and have different electrochemical potentials. The resulting corrosion depends on the type of metal and the environment.

How to protect metals from corrosion?

Corrosion is the enemy of steel, especially when used in ground structures that are in contact with the earth. But how can it be prevented? Protecting steel structures with the right primer is the best solution.

TECNA I.C.E. implements and designs a cathodic protection system (SPC) for a wide variety of structures(On-shore and Off-shore).

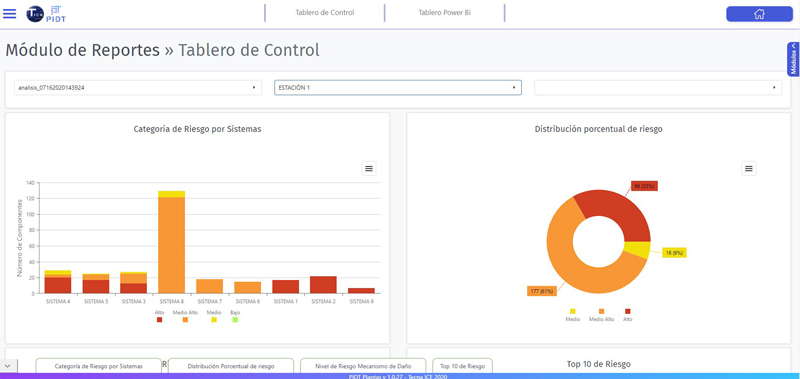

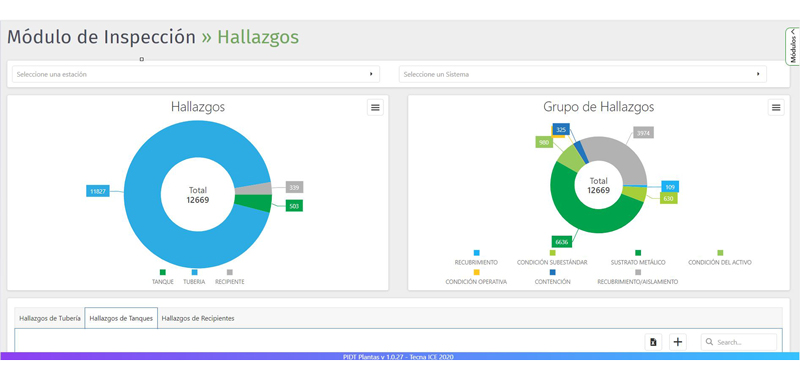

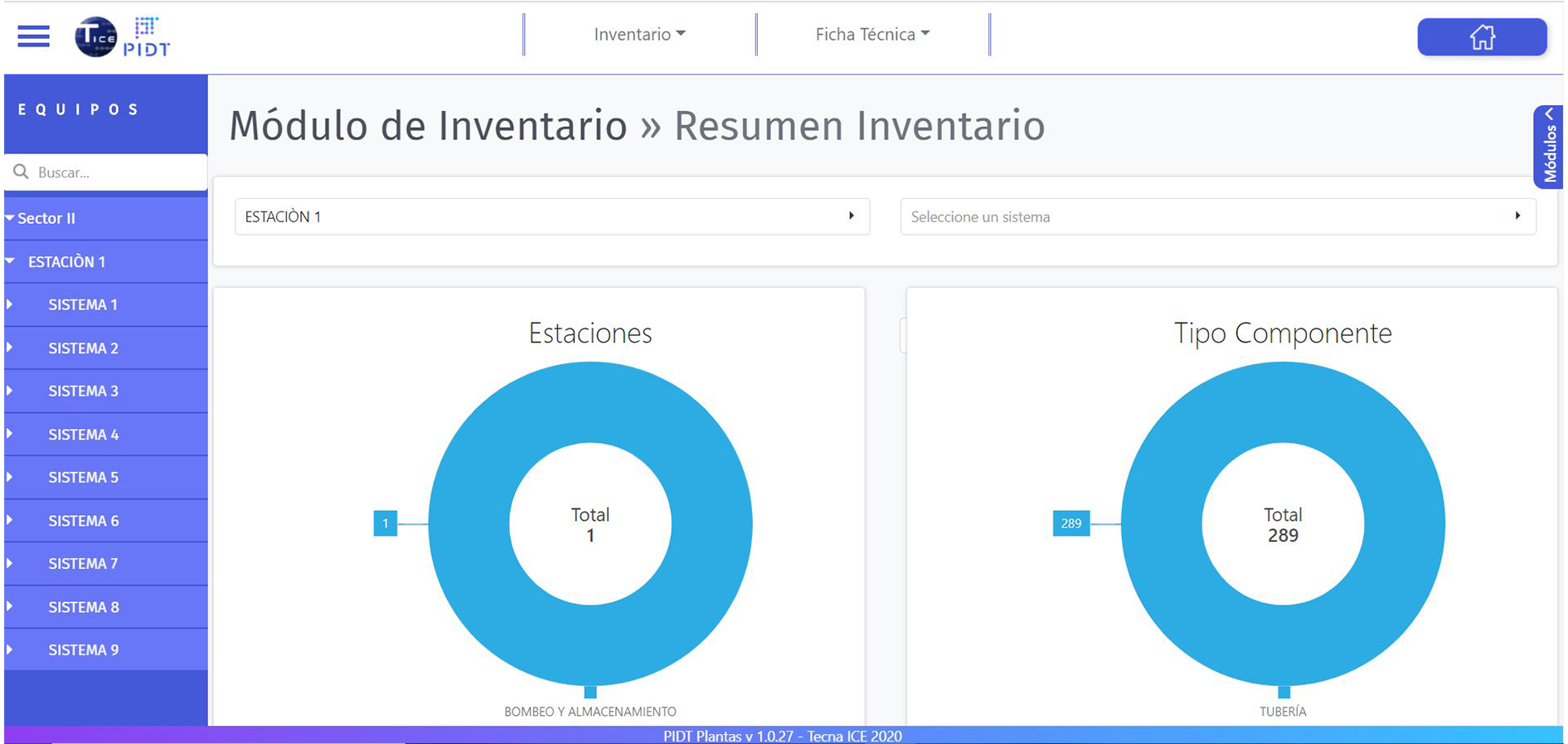

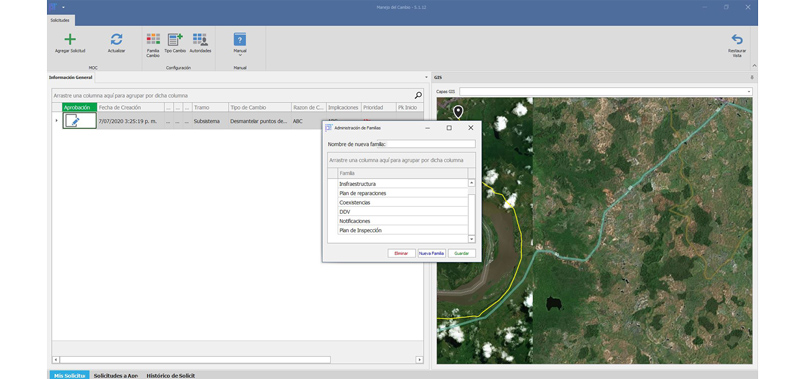

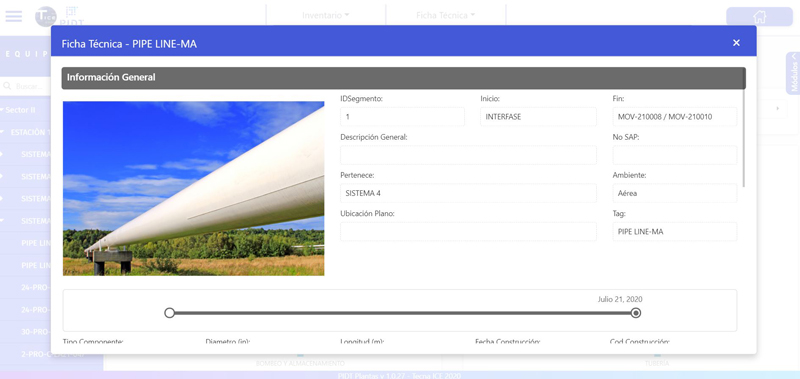

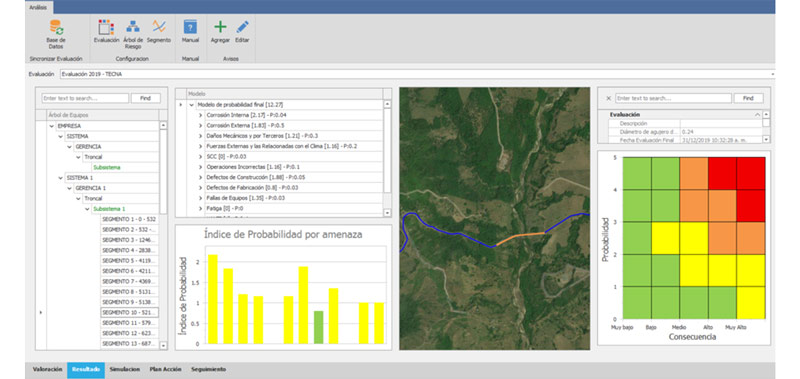

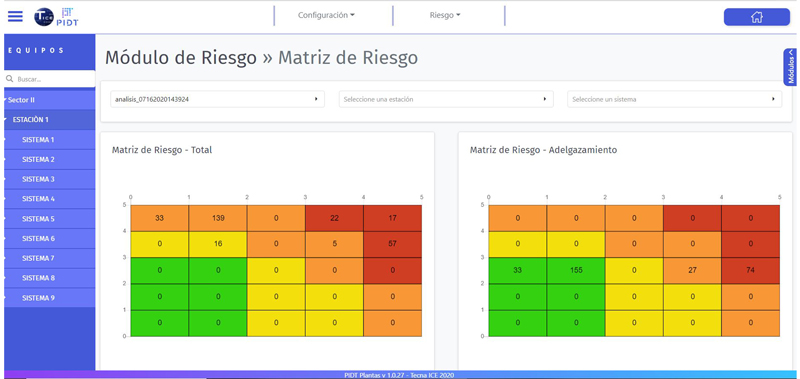

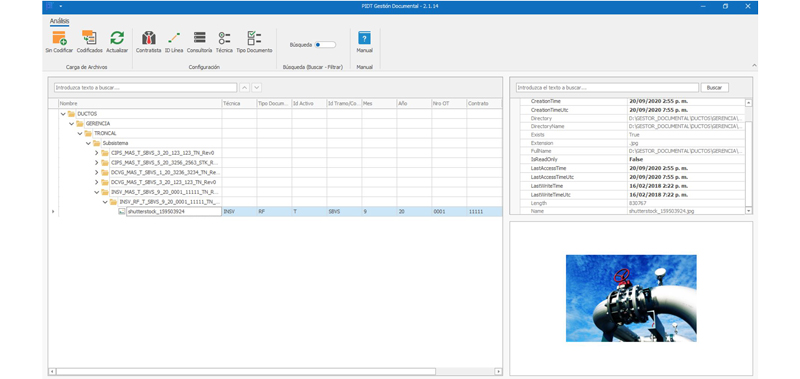

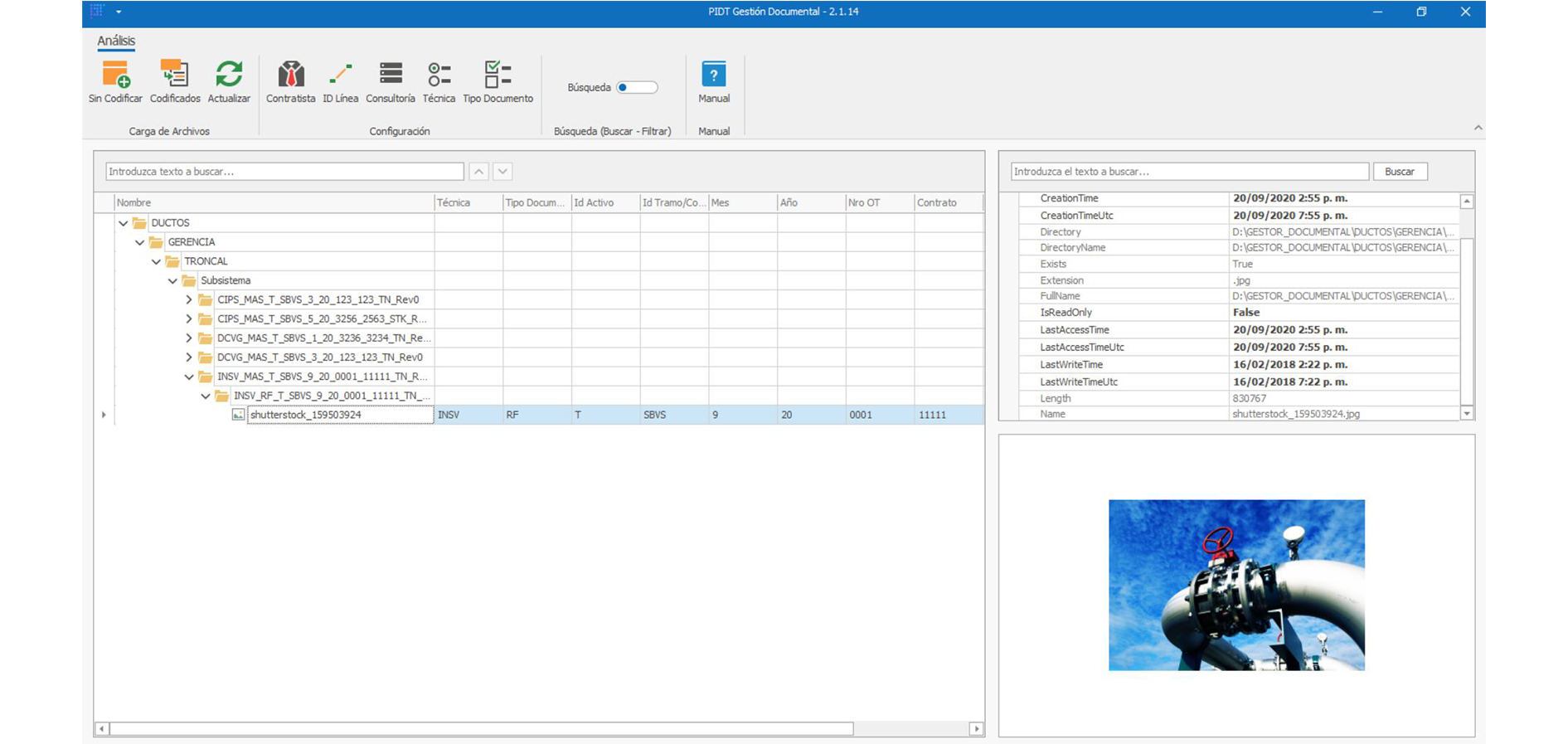

Once the cathodic protection system is implemented, you can implement our PIDT integrity software.

What is a cathodic protection system and how does it work?

Cathodic protection is a technique used to protect steel structures. The structures are electrically connected to the cathodic protection system, which consists of anodes, electrical conductors and a power supply.

The anodes are connected to the steel structures through the electrical conductors and the power supply provides the electrical current that contacts the steel structures. This will leave excess electrons on the surface of the steel structure to prevent corrosion.

There are many types of offshore and onshore structures that suffer severe damage, such as oil and gas platforms. Corrosion of offshore structure is accelerated with increasing seawater temperature or increasing seawater salinity; therefore, it is important to install a cathodic protection system to reduce these effects on offshore structures.

Did you find this content useful?

Subscribe and receive technical articles, updates and more in your inbox.

Looking for a solution like this?

Explore our specialized services in integrity engineering and applied technology.